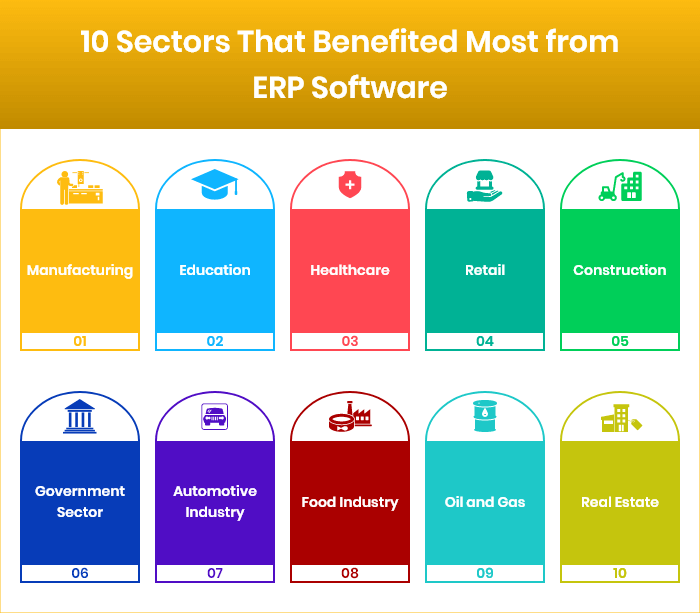

ERP system for specific industries – In the dynamic business landscape, ERP systems have emerged as indispensable tools for organizations across diverse industries. ERP systems for specific industries offer tailored solutions that address the unique challenges and requirements of each sector, empowering businesses to streamline operations, improve efficiency, and gain a competitive edge.

By integrating industry-specific functionality and modules, ERP systems cater to the specialized needs of various industries, from manufacturing and healthcare to retail and finance. These systems enable businesses to optimize processes, enhance data accuracy, and gain real-time insights into their operations.

Industry-Specific ERP Solutions

ERP systems have gained immense popularity across various industries, each with unique challenges and requirements. These systems offer tailored solutions to streamline operations, enhance efficiency, and provide real-time insights.

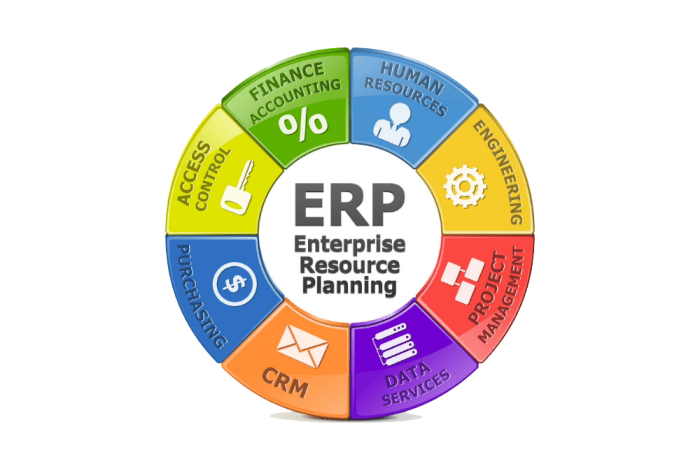

ERP systems address industry-specific challenges by integrating essential functions such as supply chain management, inventory control, customer relationship management, and financial accounting. By providing a centralized platform, ERP systems eliminate data silos, improve collaboration, and facilitate data-driven decision-making.

Manufacturing

- Complex supply chains with multiple suppliers and distributors.

- Need for real-time inventory visibility and control.

- Challenges in production planning and scheduling.

ERP systems provide manufacturers with end-to-end visibility of their operations, enabling them to optimize production processes, reduce lead times, and improve inventory management. They also facilitate collaboration between different departments, ensuring seamless communication and efficient resource allocation.

Benefits of ERP Systems for Specific Industries

ERP systems offer a multitude of advantages tailored to specific industries, leading to substantial improvements in operational efficiency, cost reduction, and enhanced decision-making.

Numerous case studies and successful ERP implementations across various sectors have demonstrated these benefits. For instance, in the manufacturing industry, ERP systems have streamlined production processes, reduced lead times, and improved inventory management, resulting in significant cost savings and increased productivity.

Return on Investment (ROI) and Cost Savings

ERP systems offer a substantial return on investment (ROI) by reducing operational costs, improving efficiency, and enhancing revenue generation.

- Reduced labor costs through automation and streamlined processes.

- Lower inventory costs due to improved demand forecasting and inventory management.

- Increased sales revenue by improving customer service and product delivery.

Key Features for Industry-Specific ERP Systems

Industry-specific ERP systems are designed to meet the unique requirements of particular sectors. These systems offer essential features and modules tailored to the specific processes, regulations, and challenges faced by each industry.

The key features of industry-specific ERP systems include:

- Industry-specific functionality:These systems incorporate pre-configured modules and workflows that align with the specific needs of the industry, such as production planning, inventory management, customer relationship management (CRM), and financial management.

- Compliance and regulatory support:Industry-specific ERP systems are designed to comply with industry-specific regulations and standards, ensuring that businesses can meet their compliance obligations.

- Best practices and industry benchmarks:These systems incorporate industry best practices and benchmarks, providing businesses with insights into industry trends and performance metrics.

- Scalability and flexibility:Industry-specific ERP systems are designed to be scalable and flexible, allowing businesses to adapt to changing market demands and business growth.

Examples of Industry-Specific ERP Solutions, ERP system for specific industries

Numerous industry-specific ERP solutions are available, tailored to meet the unique requirements of various sectors. Some examples include:

- Manufacturing ERP:Designed for manufacturers, these systems provide functionality for production planning, inventory management, quality control, and supply chain management.

- Healthcare ERP:Tailored for healthcare providers, these systems offer modules for patient management, electronic health records (EHR), billing and revenue cycle management, and compliance with healthcare regulations.

- Retail ERP:Designed for retailers, these systems provide functionality for inventory management, point-of-sale (POS) systems, customer relationship management (CRM), and supply chain management.

Integration with Industry-Specific Software

Integrating ERP systems with industry-specific software applications is crucial for businesses seeking to optimize their operations. This integration allows ERP systems to seamlessly connect with specialized software tailored to the unique requirements of their industry, enhancing data accuracy and streamlining workflows.

Common Integrations and Their Benefits

* Customer Relationship Management (CRM) Software:Integration with CRM software enables businesses to manage customer interactions, track sales opportunities, and provide personalized experiences. This integration improves customer satisfaction and increases sales conversion rates.

Supply Chain Management (SCM) Software

Integrating ERP systems with SCM software optimizes inventory management, logistics, and supplier relationships. It enhances supply chain visibility, reduces costs, and improves delivery times.

Product Lifecycle Management (PLM) Software

Integration with PLM software supports product design, development, and manufacturing processes. It facilitates collaboration among engineering, production, and sales teams, reducing product development timelines and improving product quality.

Customization and Configuration for Specific Industries

ERP systems need customization and configuration to meet industry-specific requirements. Each industry has unique processes, regulations, and workflows, and an ERP system must adapt to these specificities. For example, a manufacturing ERP system must handle production planning, inventory management, and quality control, while a healthcare ERP system must manage patient records, billing, and insurance processing.

Best Practices for Customization and Implementation

Successful customization and implementation require careful planning and execution. Best practices include:

- Involve industry experts and end-users in the customization process to ensure the system meets their needs.

- Conduct thorough testing and validation to ensure the customized system functions as intended.

- Provide ongoing support and maintenance to keep the system up-to-date and aligned with industry best practices.

Implementation Considerations for Specific Industries

Implementing ERP systems in specific industries presents unique considerations due to the distinct requirements and challenges of each sector. Understanding these considerations is crucial for successful ERP implementation.

Challenges and Opportunities

ERP implementation in different industries faces various challenges and opportunities:

- Industry-specific regulations:Complying with industry-specific regulations is essential to avoid legal and financial risks.

- Data integration:Integrating ERP systems with existing industry-specific software and legacy systems can be complex.

- Customization:Tailoring ERP systems to meet specific industry requirements often requires extensive customization.

- Process optimization:ERP implementation provides opportunities to streamline industry-specific processes, improving efficiency and productivity.

- Enhanced decision-making:ERP systems provide real-time data and insights, enabling better decision-making for industry-specific challenges.

Mitigating Risks

To mitigate risks during ERP implementation, consider the following strategies:

- Thorough planning:Conduct detailed planning and analysis to identify industry-specific requirements and potential challenges.

- Industry expertise:Partner with ERP vendors or consultants who have experience in the specific industry.

- Phased implementation:Implement the ERP system in phases to reduce disruption and allow for iterative adjustments.

- Employee training:Train employees on the new ERP system to ensure adoption and minimize resistance.

- Continuous evaluation:Monitor the ERP implementation progress and make adjustments as needed to ensure it meets industry-specific requirements.

Vendor Selection for Industry-Specific ERP Systems

Selecting the right vendor for an industry-specific ERP system is crucial for successful implementation and long-term benefits. Here are key criteria to consider:

Industry Expertise:Ensure the vendor has a deep understanding of your specific industry’s unique processes, regulations, and challenges.

Features and Functionality:Evaluate the vendor’s ERP solution for industry-specific features that meet your business requirements, such as specialized modules for production planning, inventory management, or customer relationship management.

Support and Services:Assess the vendor’s level of support, including technical assistance, industry-specific consulting, and training. Reliable and responsive support is essential for ongoing system maintenance and optimization.

Vendor Comparison Table

| Vendor | Industry Expertise | Features | Support |

|---|---|---|---|

| Vendor A | Strong in manufacturing and distribution | Advanced production planning, inventory optimization | 24/7 technical support, industry-specific consulting |

| Vendor B | Focus on healthcare and life sciences | Electronic medical records, patient management | Dedicated healthcare support team, regulatory compliance assistance |

| Vendor C | Specializes in retail and e-commerce | Omnichannel inventory management, customer loyalty programs | E-commerce integration support, digital marketing consulting |

Vendor Reputation and References:Research the vendor’s reputation in the industry, seek references from existing customers, and read online reviews to gauge their reliability and satisfaction levels.

Industry Experience:Consider the vendor’s track record of implementing ERP systems in similar industries. This experience ensures they understand the specific challenges and best practices within your sector.

Case Studies of Successful ERP Implementations

ERP implementations have revolutionized business operations across various industries. To illustrate the tangible benefits and challenges involved, let’s explore real-world case studies that showcase the transformative power of ERP systems.

Manufacturing Industry

- Case Study:A leading automobile manufacturer implemented an ERP system to streamline production processes and enhance supply chain visibility. The system integrated disparate systems, reducing lead times by 25% and improving inventory management by 15%.

- Case Study:A global consumer electronics company deployed an ERP system to automate production scheduling and optimize resource allocation. The implementation resulted in a 20% increase in production efficiency and a 12% reduction in manufacturing costs.

Retail Industry

- Case Study:A large retail chain implemented an ERP system to centralize customer data and improve inventory management. The system provided a 360-degree view of customers, leading to a 10% increase in sales and a 15% reduction in customer complaints.

- Case Study:An online retailer deployed an ERP system to streamline order fulfillment and enhance logistics operations. The implementation resulted in a 25% reduction in order processing time and a 10% increase in customer satisfaction.

Healthcare Industry

- Case Study:A multi-specialty hospital implemented an ERP system to integrate patient records, streamline billing, and optimize resource utilization. The system reduced medical errors by 15%, improved patient satisfaction by 10%, and increased revenue by 5%.

- Case Study:A large pharmaceutical company deployed an ERP system to manage clinical trials, track drug inventory, and ensure compliance with regulatory requirements. The implementation resulted in a 20% reduction in clinical trial costs and a 15% increase in product development efficiency.

Trends and Innovations in Industry-Specific ERP Systems

The ERP landscape is constantly evolving, with new trends and innovations emerging to meet the evolving needs of specific industries. These advancements are shaping the future of ERP adoption in different sectors, enabling businesses to gain a competitive edge and drive operational efficiency.

One of the key trends is the adoption of cloud-based ERP systems. Cloud ERP offers several advantages over on-premise solutions, including scalability, flexibility, and cost-effectiveness. It allows businesses to access their ERP system from anywhere, anytime, and eliminates the need for expensive hardware and maintenance.

Integration with IoT and Analytics

The integration of IoT (Internet of Things) devices with ERP systems is another emerging trend. IoT devices can collect real-time data from various sources, such as sensors and machines, and feed it into the ERP system. This data can be used to improve operational efficiency, reduce costs, and make better decisions.

Advanced analytics capabilities are also becoming increasingly important in ERP systems. These capabilities allow businesses to analyze large amounts of data to identify trends, patterns, and insights. This information can be used to improve decision-making, optimize processes, and gain a competitive advantage.

Industry-Specific Features and Functionality

ERP vendors are also developing industry-specific features and functionality to meet the unique needs of different sectors. For example, healthcare ERP systems may include features for patient management, electronic health records, and billing. Manufacturing ERP systems may include features for production planning, inventory management, and quality control.

These industry-specific features and functionality enable businesses to tailor their ERP system to their specific requirements, ensuring that it meets their unique needs and delivers maximum value.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are also playing a significant role in the evolution of ERP systems. AI and ML algorithms can be used to automate tasks, improve decision-making, and provide personalized experiences. For example, AI can be used to automate data entry, generate reports, and identify anomalies.

These trends and innovations are shaping the future of ERP adoption in different sectors. By leveraging these advancements, businesses can gain a competitive edge, drive operational efficiency, and achieve their strategic goals.

Future Outlook for Industry-Specific ERP Systems: ERP System For Specific Industries

The future of ERP systems in specific industries is poised for continued growth and innovation. Technological advancements, industry regulations, and changing business landscapes will drive the evolution of these systems, offering businesses enhanced capabilities and benefits.

Impact of Technological Advancements

Technological advancements, such as cloud computing, artificial intelligence (AI), and machine learning (ML), will significantly impact industry-specific ERP systems. Cloud-based ERP solutions provide increased flexibility, scalability, and cost-effectiveness, enabling businesses to access their ERP systems from anywhere, anytime. AI and ML algorithms can automate repetitive tasks, improve data analysis, and provide real-time insights, enhancing operational efficiency and decision-making.

Summary

In conclusion, ERP systems for specific industries provide a transformative solution for businesses seeking to optimize their operations and achieve sustained growth. By leveraging industry-specific expertise and tailored functionality, these systems empower organizations to overcome challenges, improve efficiency, and stay ahead in the competitive market landscape.

FAQ

What are the key benefits of ERP systems for specific industries?

ERP systems for specific industries offer numerous benefits, including improved efficiency, enhanced data accuracy, reduced costs, increased productivity, and better decision-making.

How can ERP systems address the unique challenges of specific industries?

ERP systems are designed to address the specific challenges of each industry by incorporating industry-specific modules and functionality. These modules cater to the unique requirements of different sectors, such as manufacturing, healthcare, retail, and finance.

What are the considerations for successful ERP implementation in specific industries?

Successful ERP implementation in specific industries requires careful planning, vendor selection, and customization. Organizations should consider the unique requirements of their industry, select a vendor with industry expertise, and tailor the ERP system to meet their specific needs.