ERP software for inventory management has revolutionized the way businesses track, manage, and optimize their inventory, transforming the complexities of inventory control into a streamlined and efficient process. Dive into this comprehensive guide to discover how ERP systems empower businesses to gain real-time visibility, optimize inventory levels, and enhance warehouse operations, driving profitability and growth.

ERP (Enterprise Resource Planning) software is a comprehensive business management solution that integrates various aspects of an organization’s operations, including inventory management. By leveraging advanced technologies and data analytics, ERP systems provide businesses with a centralized platform to manage inventory data, automate processes, and gain valuable insights to make informed decisions.

ERP Software Overview

Enterprise Resource Planning (ERP) software is a comprehensive, integrated software suite that manages and automates core business processes across an organization. It provides a single, centralized platform for managing various aspects of a business, including inventory management.

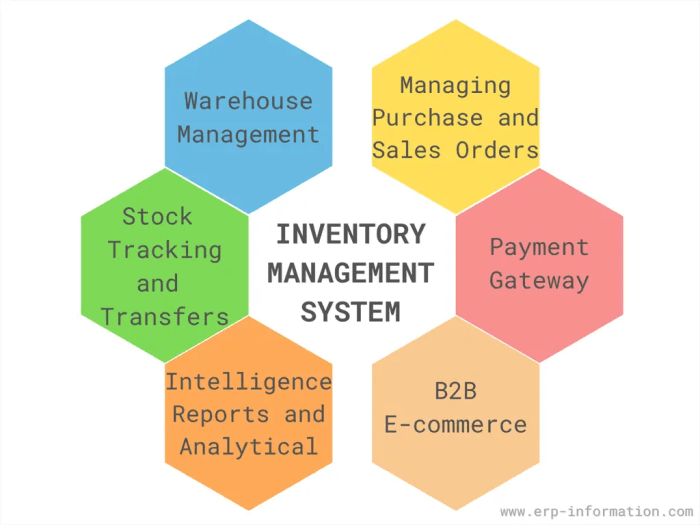

ERP software for inventory management offers several key features and benefits, including:

- Real-time inventory tracking and visibility

- Centralized inventory data and management

- Automated inventory replenishment

- Improved inventory accuracy and efficiency

- Reduced inventory costs

History and Evolution of ERP Systems

The concept of ERP systems emerged in the 1960s with the development of Material Requirements Planning (MRP) systems. MRP systems were designed to manage the flow of materials in manufacturing organizations. In the 1980s, ERP systems evolved to include additional modules for managing other business processes, such as finance, human resources, and customer relationship management.

Today, ERP systems are widely used by organizations of all sizes and industries. They provide a comprehensive solution for managing the complex challenges of modern business operations.

Inventory Management Capabilities

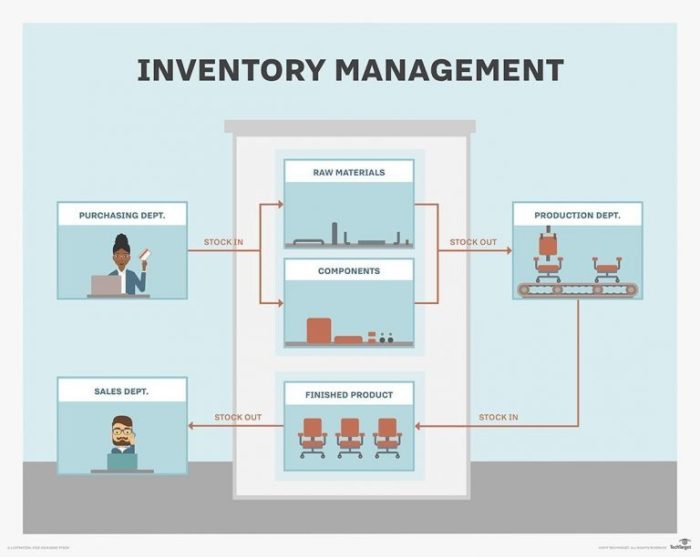

ERP software provides comprehensive inventory management capabilities to streamline and automate inventory processes. It enables businesses to track and manage inventory levels, automate inventory transactions, and optimize inventory replenishment.

ERP systems provide real-time visibility into inventory levels across multiple locations and warehouses. They track inventory movements, such as receipts, shipments, and adjustments, in real time, providing up-to-date information on inventory availability.

Inventory Transactions

ERP systems automate inventory transactions, reducing the risk of errors and improving efficiency. They can automatically generate purchase orders when inventory levels fall below predetermined thresholds, ensuring timely replenishment.

ERP systems also automate the receiving process, matching purchase orders with incoming shipments and updating inventory records accordingly. They can generate goods received notes (GRNs) and automatically update inventory levels based on the received quantities.

Inventory Optimization

ERP systems help businesses optimize inventory levels to minimize carrying costs and prevent stockouts. They use algorithms to analyze historical demand patterns, lead times, and safety stock levels to determine optimal inventory levels for each item.

ERP systems can also provide insights into inventory performance, such as inventory turnover rates and days of inventory on hand. This information helps businesses identify areas for improvement and make informed decisions about inventory management strategies.

Real-Time Inventory Visibility

Real-time inventory visibility is crucial for businesses to maintain optimal stock levels, prevent stockouts, and improve overall inventory management. It provides businesses with an accurate and up-to-date view of their inventory levels across multiple locations and channels.

ERP software plays a vital role in providing real-time inventory visibility by integrating data from various sources, including warehouses, distribution centers, and point-of-sale systems. This integrated data allows businesses to track inventory movements in real-time, providing a comprehensive view of inventory levels and availability.

Benefits of Real-Time Inventory Visibility

- Improved inventory accuracy

- Reduced stockouts

- Optimized stock levels

- Enhanced customer satisfaction

- Increased efficiency in inventory management

Inventory Optimization

ERP software plays a pivotal role in optimizing inventory levels, enabling businesses to minimize costs while ensuring optimal stock availability.

Inventory optimization techniques supported by ERP systems include:

Demand Forecasting

- Predicts future demand based on historical data, seasonal trends, and market analysis.

- Helps businesses maintain appropriate stock levels to meet customer demand while avoiding overstocking.

Safety Stock Management

- Calculates the optimal safety stock levels to buffer against unexpected demand fluctuations or supply chain disruptions.

- Prevents stockouts and ensures uninterrupted operations.

Reorder Point Optimization

- Determines the optimal reorder point to trigger purchase orders when inventory levels reach a predefined threshold.

- Ensures timely replenishment and prevents stockouts.

Inventory Turnover Analysis, ERP software for inventory management

- Calculates the rate at which inventory is sold and replaced.

- Helps identify slow-moving or obsolete inventory items for timely disposal.

ABC Analysis

- Classifies inventory items based on their value and demand.

- Enables businesses to focus their inventory management efforts on high-value items that contribute significantly to revenue.

Warehouse Management

ERP software plays a pivotal role in optimizing warehouse operations by centralizing data, streamlining processes, and providing real-time visibility into inventory levels and warehouse activities.

Through integrated modules, ERP systems automate various warehouse functions, such as inventory tracking, order fulfillment, and shipping management, resulting in increased efficiency and reduced operational costs.

Inventory Tracking

- ERP software provides real-time inventory visibility across multiple warehouses and locations, ensuring accurate stock levels and eliminating discrepancies.

- Automated inventory tracking eliminates manual processes, reducing errors and improving inventory accuracy.

- By integrating with barcode scanners and RFID technology, ERP systems enable efficient inventory tracking and cycle counting.

Order Fulfillment

- ERP software streamlines order fulfillment by automating order processing, picking, and packing.

- Integration with warehouse management systems (WMS) optimizes picking routes and reduces order fulfillment time.

- Real-time inventory visibility ensures that orders are fulfilled accurately and efficiently.

Shipping Management

- ERP software integrates with shipping carriers to automate shipping processes, including label printing and tracking.

- Automated shipping management reduces errors, improves shipping accuracy, and streamlines the entire shipping process.

- Integration with customer relationship management (CRM) systems provides real-time shipping updates to customers.

Integration with Other Business Systems

Integrating ERP software with other business systems is crucial for streamlining operations and improving overall business efficiency. ERP systems can seamlessly connect with various software applications, including CRM (Customer Relationship Management), accounting, supply chain management, and e-commerce platforms.

By integrating with CRM systems, ERP software can access customer data, track interactions, and manage sales pipelines. This integration enables businesses to provide personalized customer experiences, improve lead management, and optimize sales forecasting.

Accounting Integration

Integrating with accounting software allows ERP systems to automate financial processes, such as accounts payable, accounts receivable, and general ledger management. This integration eliminates manual data entry, reduces errors, and provides real-time visibility into financial data.

Vendor Management: ERP Software For Inventory Management

ERP software plays a crucial role in helping businesses manage their relationships with vendors. By providing a centralized platform for vendor data, communication, and collaboration, ERP systems streamline the vendor management process and enhance efficiency.

Vendor Data Management

- ERP systems enable businesses to store and organize comprehensive vendor data, including contact information, payment terms, purchase history, and performance metrics.

- This centralized data repository provides a single source of truth, eliminating the need for multiple spreadsheets or disparate systems, and ensuring data accuracy and consistency.

Vendor Communication and Collaboration

- ERP systems facilitate seamless communication and collaboration between businesses and their vendors.

- Through integrated messaging, document sharing, and workflow automation, ERP systems streamline vendor communication, reducing delays and improving response times.

Vendor Performance Evaluation

- ERP systems provide robust tools for evaluating vendor performance, including metrics such as delivery times, product quality, and customer service.

- By tracking and analyzing vendor performance, businesses can identify areas for improvement and make informed decisions about vendor selection and retention.

Demand Forecasting

ERP software plays a pivotal role in demand forecasting for inventory items, enabling businesses to anticipate future demand patterns and optimize inventory levels accordingly. ERP systems leverage data analysis techniques to analyze historical sales data, market trends, and other relevant factors to predict future demand.

Predictive Analytics

ERP systems employ predictive analytics to forecast demand based on historical data. They analyze trends, seasonality, and customer behavior to identify patterns and develop predictive models. These models help businesses forecast future demand with greater accuracy, allowing them to make informed decisions about inventory levels, production schedules, and purchasing strategies.

Data Integration

ERP systems integrate data from various sources, including sales, marketing, and finance, to provide a comprehensive view of demand patterns. This data integration enables businesses to analyze demand across different channels, regions, and customer segments, leading to more accurate and granular forecasts.

Collaboration and Communication

ERP software facilitates collaboration and communication between different departments involved in inventory management, including sales, purchasing, and operations. This enables businesses to share demand forecasts and align their strategies to meet customer needs effectively.

Benefits of Demand Forecasting

Accurate demand forecasting offers several benefits to businesses, including:

- Reduced inventory costs by optimizing inventory levels and minimizing overstocking or understocking.

- Improved customer service by ensuring product availability and minimizing stockouts.

- Enhanced planning and decision-making by providing insights into future demand patterns.

- Increased efficiency in supply chain management by aligning production and purchasing schedules with demand forecasts.

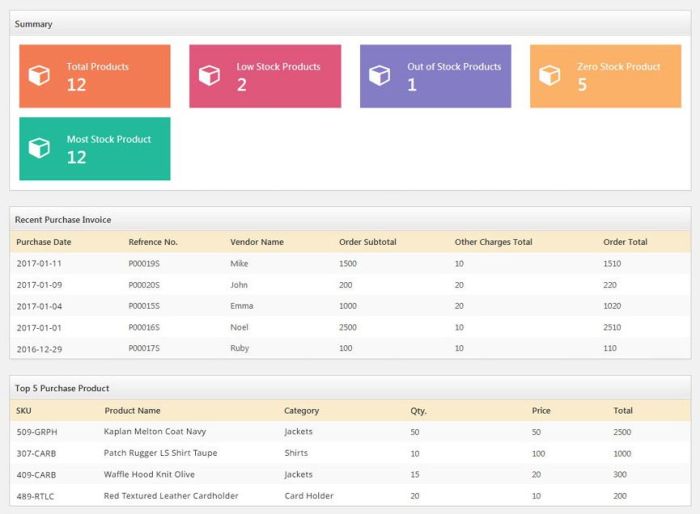

Reporting and Analytics

ERP software for inventory management provides comprehensive reporting and analytics capabilities that help businesses gain valuable insights into their inventory data. These capabilities enable businesses to analyze inventory trends, identify areas for improvement, and make informed decisions.

Inventory Reports

ERP software generates various inventory reports that provide detailed information about inventory levels, stock movements, and other key metrics. These reports include:

- Stock Status Report: Provides a snapshot of current inventory levels, including on-hand quantities, committed quantities, and available quantities.

- Inventory Turnover Report: Calculates the rate at which inventory is sold and replaced, indicating the efficiency of inventory management.

- Inventory Ageing Report: Shows the age of inventory items, helping businesses identify slow-moving or obsolete stock.

Inventory Dashboards

In addition to reports, ERP software offers customizable dashboards that provide real-time visibility into key inventory metrics. These dashboards can be tailored to specific user roles and responsibilities, providing personalized insights.Common inventory dashboards include:

- Inventory Performance Dashboard: Displays overall inventory performance metrics, such as inventory turnover, stockout rates, and lead times.

- Warehouse Management Dashboard: Provides insights into warehouse operations, including inventory levels, storage utilization, and order fulfillment rates.

- Vendor Management Dashboard: Tracks vendor performance, including delivery times, quality metrics, and pricing.

By leveraging the reporting and analytics capabilities of ERP software, businesses can improve inventory visibility, optimize inventory levels, and make data-driven decisions to enhance inventory management operations.

Case Studies

Numerous businesses have experienced significant improvements by implementing ERP software for inventory management. These case studies demonstrate the tangible benefits and successful outcomes achieved.

One notable example is a manufacturing company that struggled with inventory inaccuracies and inefficient warehouse operations. After implementing an ERP system, they gained real-time visibility into their inventory levels, enabling them to optimize stock levels, reduce waste, and improve customer service.

Improved Inventory Accuracy

- Reduced inventory discrepancies by 90%

- Eliminated manual counting and data entry errors

- Improved product availability and customer satisfaction

Enhanced Warehouse Efficiency

- Reduced warehouse labor costs by 25%

- Optimized warehouse layout and storage strategies

- Increased order fulfillment speed and accuracy

Streamlined Vendor Management

- Centralized vendor communication and purchase orders

- Improved vendor performance monitoring and supplier negotiations

- Reduced procurement costs and lead times

Best Practices

Implementing and using ERP software for inventory management can yield significant benefits. By following best practices, organizations can maximize the value of their ERP investment and optimize their inventory management processes.

Best practices for implementing and using ERP software for inventory management include:

Data Management

- Establish clear data ownership and responsibilities.

- Implement data validation and cleansing processes to ensure data accuracy and consistency.

- Regularly review and update inventory data to maintain its relevance and accuracy.

System Configuration

- Configure the ERP system to meet the specific needs of the organization.

- Establish clear inventory management policies and procedures and configure the system accordingly.

- Set up automated alerts and notifications to monitor inventory levels and identify potential issues.

User Training

- Provide comprehensive training to all users of the ERP system.

- Ensure users understand the inventory management functionality of the system and how to use it effectively.

- Offer ongoing support and training to users to keep them up-to-date on new features and best practices.

Outcome Summary

In conclusion, ERP software for inventory management is an indispensable tool for businesses seeking to streamline operations, optimize inventory levels, and gain a competitive edge. By embracing the capabilities of ERP systems, businesses can achieve real-time inventory visibility, automate inventory processes, enhance warehouse efficiency, and make data-driven decisions to drive growth and profitability.

Implementing ERP software for inventory management is a strategic investment that empowers businesses to navigate the complexities of inventory management with confidence and efficiency.

Popular Questions

What are the key benefits of using ERP software for inventory management?

ERP software for inventory management offers numerous benefits, including real-time inventory visibility, automated inventory processes, optimized inventory levels, enhanced warehouse efficiency, and improved demand forecasting.

How does ERP software help businesses optimize inventory levels?

ERP systems utilize advanced algorithms and data analysis to determine optimal inventory levels based on historical data, demand forecasting, and lead times. This helps businesses reduce overstocking, minimize stockouts, and optimize cash flow.

What is the role of ERP software in warehouse management?

ERP software streamlines warehouse operations by providing real-time inventory visibility, optimizing warehouse layout, and automating tasks such as inventory receiving, put-away, and picking. This enhances warehouse efficiency, reduces errors, and improves productivity.