ERP software for continuous improvement is revolutionizing the way organizations approach process optimization, data analysis, and performance tracking. By leveraging its core capabilities, businesses can streamline data collection, facilitate collaboration, and drive informed decision-making, ultimately propelling their continuous improvement initiatives to new heights.

In this comprehensive guide, we delve into the key features, benefits, implementation considerations, and best practices of ERP software for continuous improvement. We explore real-world case studies, emerging trends, and potential challenges to provide a holistic understanding of this transformative technology.

Key Features of ERP Software for Continuous Improvement

ERP software designed for continuous improvement provides organizations with a comprehensive set of tools and capabilities to enhance their processes and drive operational excellence. These solutions offer core functionalities that support various aspects of continuous improvement initiatives, including:

Process Optimization:

- Process mapping and modeling tools enable organizations to visualize and analyze their existing processes, identify inefficiencies, and design improved workflows.

- Workflow automation capabilities streamline tasks and reduce manual effort, freeing up resources for value-added activities.

- Integration with other systems, such as CRM and SCM, provides a holistic view of business operations, facilitating cross-functional collaboration and process optimization.

Data Analysis:

- Advanced reporting and analytics tools allow organizations to collect, analyze, and interpret data from various sources, including ERP systems, sensors, and external databases.

- Data visualization capabilities, such as dashboards and charts, help organizations quickly identify trends, patterns, and outliers, enabling informed decision-making.

- Predictive analytics models can be integrated to forecast future performance, identify potential risks, and optimize resource allocation.

Performance Tracking:

- Key performance indicators (KPIs) can be defined and tracked to measure progress towards continuous improvement goals.

- Real-time monitoring dashboards provide visibility into operational performance, allowing organizations to respond quickly to deviations and take corrective actions.

- Benchmarking capabilities enable organizations to compare their performance against industry standards and best practices, identifying areas for improvement.

Benefits of Using ERP Software for Continuous Improvement

ERP software offers a range of advantages for organizations seeking to enhance their continuous improvement efforts. By leveraging this technology, businesses can streamline data collection, facilitate collaboration, and drive more informed decision-making.

One of the key benefits of ERP software for continuous improvement is its ability to streamline data collection. ERP systems centralize data from across the organization, providing a single source of truth for performance metrics and improvement opportunities. This eliminates the need for manual data entry and reduces the risk of errors, ensuring that decision-makers have access to accurate and timely information.

Facilitating Collaboration

ERP software also facilitates collaboration by providing a platform for cross-functional teams to share ideas and insights. The centralized data repository allows users from different departments to access and analyze the same information, fostering a collaborative approach to problem-solving and improvement. This enhances communication and coordination, leading to more effective and efficient continuous improvement initiatives.

Driving Decision-Making

Finally, ERP software plays a crucial role in driving decision-making by providing real-time insights into performance and improvement opportunities. Through advanced analytics and reporting capabilities, ERP systems help organizations identify trends, pinpoint areas for improvement, and evaluate the effectiveness of improvement initiatives. This data-driven approach enables decision-makers to make informed choices and prioritize improvement efforts based on objective data and analysis.

Implementation Considerations for ERP Software in Continuous Improvement

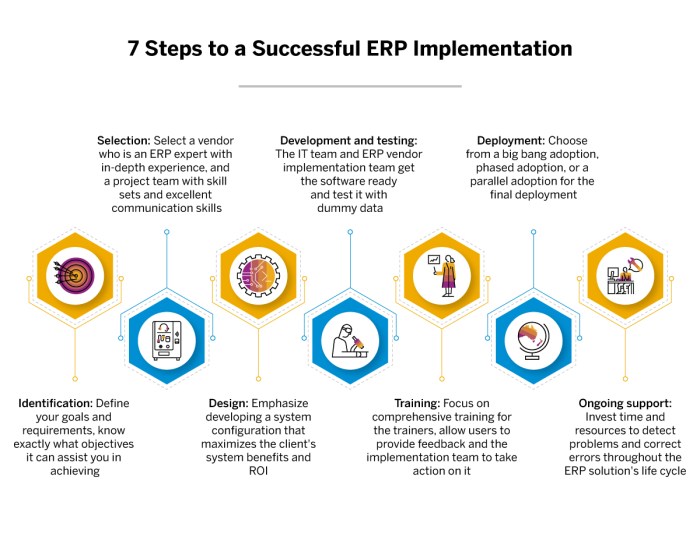

The successful implementation of ERP software for continuous improvement requires careful planning and consideration of several key factors. These include data integration, user adoption, and change management strategies.

Data integration is crucial to ensure that all relevant data is captured and accessible within the ERP system. This includes data from various sources, such as production, quality control, and customer feedback. Effective data integration enables comprehensive analysis and reporting, which are essential for continuous improvement efforts.

User Adoption

User adoption is another critical aspect of successful ERP implementation. Users must be trained and supported to effectively utilize the system’s features and capabilities. This involves providing clear documentation, training materials, and ongoing support to ensure that users are comfortable and proficient in using the software.

Change Management

Implementing ERP software often involves significant changes to existing processes and workflows. To mitigate resistance and ensure a smooth transition, organizations should develop a comprehensive change management strategy. This strategy should include communication plans, training programs, and support mechanisms to help users adapt to the new system and embrace the benefits it offers.

Best Practices for Utilizing ERP Software for Continuous Improvement

ERP software can be a powerful tool for continuous improvement, but only if it is used effectively. Here are some best practices to help you maximize the effectiveness of your ERP software for continuous improvement:

Data analysis is a critical part of continuous improvement. ERP software can provide you with a wealth of data that can be used to identify areas for improvement. Use data analysis tools to identify trends, patterns, and outliers. This information can help you to identify areas where you can make improvements to your processes.

Process Mapping

Process mapping is another important tool for continuous improvement. ERP software can help you to create visual representations of your processes. This can help you to identify bottlenecks, inefficiencies, and other areas for improvement.

Performance Measurement, ERP software for continuous improvement

Performance measurement is essential for tracking your progress and identifying areas for improvement. ERP software can help you to track key performance indicators (KPIs) and compare your performance to industry benchmarks. This information can help you to identify areas where you need to make improvements.

Case Studies of Successful ERP Software Implementations for Continuous Improvement

Organizations across various industries have realized significant benefits by implementing ERP software for continuous improvement. These case studies highlight real-world examples of successful implementations and the challenges faced along the way.

One notable example is a manufacturing company that implemented an ERP system to streamline its production processes and improve quality control. The ERP system provided real-time data on production metrics, enabling the company to identify bottlenecks and make data-driven decisions for process optimization.

As a result, the company reduced production lead times by 20% and significantly improved product quality.

Challenges and Results

While ERP software offers numerous advantages, organizations may encounter challenges during implementation. One common challenge is resistance to change from employees accustomed to existing processes. To overcome this, it’s crucial to involve employees in the implementation process and provide adequate training to ensure a smooth transition.

Another challenge is the need for data integration from multiple sources. ERP systems require accurate and consistent data to provide meaningful insights. Organizations should establish a data governance strategy to ensure data integrity and reliability.

Despite these challenges, organizations that successfully implement ERP software for continuous improvement often experience significant results. Improved data visibility, streamlined processes, and enhanced collaboration can lead to increased efficiency, reduced costs, and improved customer satisfaction.

Integration with Other Tools and Systems for Continuous Improvement

Integrating ERP software with other tools and systems is crucial for enhancing continuous improvement efforts. This integration enables seamless data flow, facilitates real-time decision-making, and streamlines collaboration among different teams involved in the improvement process.

Integrating ERP software with data analytics platforms, for instance, provides real-time insights into key performance indicators (KPIs), enabling organizations to identify areas for improvement and track progress effectively. Additionally, integrating with project management tools helps manage and monitor improvement initiatives, ensuring timely completion and adherence to timelines.

Integration with Quality Management Systems

Integrating ERP software with quality management systems (QMS) enables organizations to centralize quality-related data, streamline non-conformance reporting, and automate corrective and preventive action (CAPA) processes. This integration ensures that quality issues are identified and addressed promptly, contributing to continuous improvement in product or service quality.

Emerging Trends in ERP Software for Continuous Improvement

ERP software is constantly evolving to meet the changing needs of businesses. In the area of continuous improvement, several emerging trends are shaping the future of how organizations approach and achieve operational excellence. These advancements are transforming data analysis, process automation, and collaboration, enabling businesses to gain deeper insights, streamline operations, and drive continuous improvement efforts more effectively.

Data Analytics and AI

- Advanced data analytics capabilities are being integrated into ERP systems, allowing businesses to collect, analyze, and visualize data from multiple sources in real-time.

- Artificial intelligence (AI) and machine learning (ML) algorithms are being leveraged to automate data analysis tasks, identify patterns and trends, and provide predictive insights.

- These advancements enable organizations to make data-driven decisions, identify areas for improvement, and proactively address potential issues.

Process Automation and RPA

- Robotic process automation (RPA) is being integrated with ERP systems to automate repetitive and time-consuming tasks, such as data entry, order processing, and invoice reconciliation.

- RPA bots can be programmed to follow specific rules and instructions, freeing up human resources to focus on more complex and value-added activities.

- Process automation streamlines operations, reduces errors, and improves efficiency, allowing organizations to allocate resources more effectively.

Collaboration and Communication

- ERP systems are becoming more collaborative, with features that facilitate communication and knowledge sharing among team members.

- Social media-like functionality, discussion forums, and instant messaging capabilities enable employees to share ideas, provide feedback, and work together on improvement initiatives.

- Enhanced collaboration fosters a culture of continuous improvement, where employees are empowered to contribute and share their expertise.

Challenges and Limitations of Using ERP Software for Continuous Improvement

ERP software for continuous improvement offers numerous benefits, but it also comes with potential challenges and limitations.One challenge lies in the complexity of ERP systems. Implementing and maintaining an ERP system can be a complex and time-consuming process, requiring significant resources and expertise.

Organizations may face difficulties in customizing the software to meet their specific needs, leading to potential disruptions and inefficiencies.Another limitation is the potential for data accuracy and integrity issues. ERP systems rely heavily on data input, and any errors or inconsistencies in the data can lead to inaccurate reports and decision-making.

Maintaining data accuracy requires robust data governance practices and ongoing data validation processes.Additionally, the cost of implementing and maintaining ERP software can be a significant investment for organizations. ERP systems often require ongoing maintenance, upgrades, and support, which can add to the overall cost of ownership.

Organizations should carefully consider the return on investment (ROI) and ensure that the benefits of using ERP software outweigh the costs.

Future Outlook for ERP Software in Continuous Improvement

ERP software is expected to continue playing a vital role in continuous improvement initiatives. As organizations strive for operational excellence, the demand for robust and integrated solutions will grow.

Advancements in technology, integration, and data analytics capabilities will further enhance the effectiveness of ERP software for continuous improvement.

Integration with Emerging Technologies

- Integration with artificial intelligence (AI) and machine learning (ML) algorithms will enable ERP systems to automate data analysis, identify patterns, and make predictive recommendations for improvement opportunities.

- The Internet of Things (IoT) will connect ERP systems to sensors and devices, providing real-time data on production processes and equipment performance, facilitating proactive monitoring and predictive maintenance.

- Blockchain technology can enhance data security and transparency, enabling organizations to securely share data with partners and suppliers, fostering collaboration and knowledge sharing for continuous improvement.

Enhanced Data Analytics Capabilities

- Advanced data analytics tools will provide deeper insights into process performance, enabling organizations to identify bottlenecks, reduce waste, and optimize resource allocation.

- Real-time dashboards and reporting capabilities will empower decision-makers with up-to-date information, allowing for agile responses to changing conditions and continuous improvement initiatives.

- Predictive analytics will help organizations forecast future performance, anticipate potential issues, and proactively take corrective actions, driving continuous improvement efforts.

Closing Summary

ERP software for continuous improvement is not just a tool; it’s a catalyst for organizational transformation. By embracing its capabilities, businesses can unlock a wealth of opportunities to enhance efficiency, drive innovation, and achieve sustainable growth. As technology continues to evolve, ERP software will undoubtedly remain at the forefront of continuous improvement efforts, empowering organizations to navigate the ever-changing business landscape with agility and resilience.

Helpful Answers: ERP Software For Continuous Improvement

What are the key features of ERP software for continuous improvement?

ERP software for continuous improvement offers a range of core capabilities, including process optimization modules, data analysis tools, performance tracking dashboards, and collaboration platforms.

How does ERP software benefit continuous improvement efforts?

ERP software streamlines data collection, facilitates collaboration, enhances decision-making, and provides real-time insights into process performance.

What are the challenges of implementing ERP software for continuous improvement?

Potential challenges include data integration, user adoption, change management, and ensuring alignment with organizational goals.