In the realm of asset management, ERP software for maintainability emerges as a game-changer, revolutionizing the way organizations approach maintenance operations. By leveraging the power of ERP systems, businesses can streamline maintenance processes, reduce downtime, and enhance asset utilization, leading to increased productivity and profitability.

ERP software for maintainability empowers organizations to gain a comprehensive view of their assets, track maintenance history, schedule preventive maintenance, and monitor asset performance. This centralized platform provides a single source of truth for maintenance data, eliminating the risk of errors and inconsistencies.

Definition of ERP Software for Maintainability

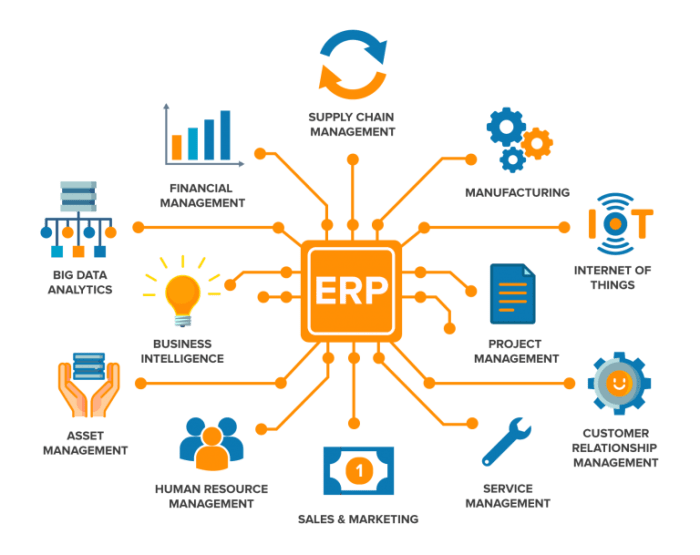

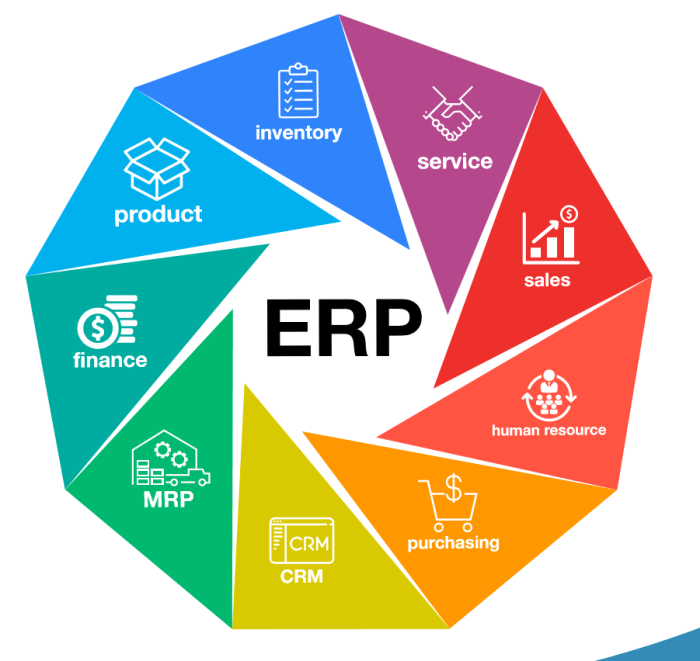

Enterprise Resource Planning (ERP) software is a comprehensive business management solution that integrates various departments and functions within an organization, including maintenance and asset management. ERP systems play a crucial role in enhancing maintainability by providing a centralized platform for managing maintenance-related data, processes, and activities.

Key features and functionalities of ERP systems that enhance maintainability include:

- Centralized Maintenance Data Management:ERP systems provide a single repository for storing and managing all maintenance-related data, including asset information, maintenance history, work orders, and spare parts inventory.

- Preventive Maintenance Scheduling:ERP systems enable organizations to establish and manage preventive maintenance schedules based on asset usage, operating hours, or other defined criteria, helping to prevent unplanned downtime and extend asset life.

- Work Order Management:ERP systems streamline the work order process, from creation and assignment to tracking and completion. This ensures that maintenance tasks are executed efficiently and effectively.

- Spare Parts Inventory Management:ERP systems provide real-time visibility into spare parts inventory levels, allowing organizations to optimize inventory levels and avoid stockouts, ensuring that critical spare parts are available when needed.

- Maintenance Cost Tracking:ERP systems track maintenance costs and expenses, enabling organizations to analyze and optimize maintenance budgets, identify areas for cost savings, and make informed decisions.

- Integration with Other Systems:ERP systems can integrate with other business systems, such as CMMS (Computerized Maintenance Management Systems), to provide a comprehensive view of maintenance operations and streamline data exchange.

Benefits of Using ERP Software for Maintainability

ERP software offers numerous advantages for improving maintainability, empowering organizations to enhance their operational efficiency and reduce downtime.

The benefits of using ERP software for maintainability include:

Reduced Downtime

ERP software provides a centralized platform for managing maintenance activities, enabling organizations to streamline work orders, track asset performance, and schedule preventive maintenance. This proactive approach helps identify and address potential issues before they escalate into major breakdowns, reducing unplanned downtime and ensuring optimal equipment performance.

Increased Asset Utilization

ERP software provides real-time visibility into asset availability and utilization, allowing organizations to optimize their maintenance strategies. By monitoring asset performance and usage patterns, organizations can identify underutilized assets and redeploy them to areas where they can generate more value.

This efficient utilization of assets leads to increased productivity and cost savings.

Improved Compliance

ERP software helps organizations maintain compliance with industry regulations and standards related to maintenance. By providing a comprehensive audit trail of maintenance activities, organizations can demonstrate adherence to regulatory requirements and reduce the risk of fines or penalties. Additionally, ERP software can automate compliance-related tasks, such as generating maintenance reports and tracking certifications, ensuring accuracy and efficiency.

Challenges of Implementing ERP Software for Maintainability

Implementing ERP software for maintainability brings numerous benefits, but it also presents several challenges that organizations must address to ensure successful implementation and maximize the software’s potential.

These challenges encompass various aspects of ERP implementation, including data integration, change management, and cost and resource constraints.

Data Integration

ERP software for maintainability relies on the integration of data from multiple sources, including maintenance records, asset data, and work orders. This data integration can be challenging due to:

- Data inconsistencies:Data from different sources may be inconsistent, requiring extensive cleaning and harmonization efforts.

- Data redundancy:Duplicate data can exist across multiple systems, leading to data inaccuracies and inefficiencies.

- Data security:Integrating data from various sources raises data security concerns, requiring robust security measures to protect sensitive information.

Change Management

ERP software implementation involves significant changes in business processes and workflows. These changes can impact employees, requiring effective change management strategies to:

- Communicate changes effectively:Employees need to be informed about the benefits and impact of the new software, as well as their roles and responsibilities.

- Provide training and support:Comprehensive training and support programs are crucial to ensure employees can use the software effectively.

- Manage resistance to change:Resistance to change is common during ERP implementation. Change management strategies should address employee concerns and provide support to minimize resistance.

Cost and Resource Constraints

ERP software implementation can be costly and resource-intensive. Organizations need to carefully consider the following:

- Software licensing fees:ERP software licenses can be expensive, especially for larger organizations.

- Implementation costs:Implementing ERP software requires significant investment in hardware, software, and consulting services.

- Ongoing maintenance costs:ERP software requires ongoing maintenance and support, which can add to the total cost of ownership.

- Resource availability:Implementing ERP software requires dedicated resources, including IT staff, business analysts, and end-users, which may strain organizational resources.

Best Practices for Implementing ERP Software for Maintainability

Implementing ERP software for maintainability requires careful planning and execution. Here are some industry best practices to ensure a successful implementation:

Establishing Clear Goals and Objectives:

- Define specific and measurable goals for the ERP implementation, focusing on improving maintainability.

- Establish key performance indicators (KPIs) to track progress and measure the effectiveness of the software.

Engaging Stakeholders:

- Involve all relevant stakeholders, including maintenance personnel, managers, and end-users, throughout the implementation process.

- Gather input and feedback from stakeholders to ensure the ERP system meets their needs and expectations.

Utilizing a Phased Approach:

- Implement the ERP software in phases, starting with critical areas of maintainability.

- This allows for a more controlled implementation, reduces risks, and provides opportunities for feedback and adjustments.

Case Studies of Successful ERP Software Implementations for Maintainability

Organizations worldwide have successfully implemented ERP software to enhance maintainability, resulting in improved efficiency, reduced costs, and increased uptime. These case studies provide valuable insights into the challenges and benefits experienced by real-world organizations.

Case Study: Manufacturing Company

A global manufacturing company implemented an ERP system to streamline its maintenance processes. The company faced challenges with fragmented data, lack of visibility into maintenance schedules, and inefficient communication between maintenance teams. The ERP system integrated maintenance data, provided real-time visibility, and automated communication, leading to:

- Reduced maintenance downtime by 25%

- Improved equipment utilization by 15%

- Reduced maintenance costs by 10%

Case Study: Healthcare Facility

A large healthcare facility implemented an ERP system to improve the efficiency of its maintenance operations. The facility faced challenges with manual maintenance tracking, lack of inventory control, and inefficient scheduling. The ERP system automated maintenance processes, provided real-time inventory visibility, and optimized scheduling, resulting in:

- Reduced maintenance backlog by 30%

- Improved equipment uptime by 20%

- Reduced inventory costs by 15%

Metrics for Measuring the Success of ERP Software for Maintainability

Measuring the success of ERP software for maintainability is crucial to ensure it meets the desired objectives. Key performance indicators (KPIs) and metrics provide valuable insights into the effectiveness of the software in improving maintainability.

KPIs for Measuring Maintainability

Key performance indicators (KPIs) are quantifiable measures that track the progress and effectiveness of ERP software in improving maintainability. Common KPIs include:

- Mean Time to Repair (MTTR):Measures the average time taken to repair or restore equipment or assets to operational status.

- Mean Time Between Failures (MTBF):Indicates the average time between equipment or asset failures.

- Overall Equipment Effectiveness (OEE):Calculates the percentage of time equipment is available, operating, and producing at optimal efficiency.

- Maintenance Costs:Tracks the total costs associated with maintenance activities, including labor, parts, and materials.

Tracking and Analyzing Metrics

Regularly tracking and analyzing these metrics allows organizations to:

- Identify areas for improvement:Metrics can pinpoint areas where maintainability is lacking, enabling targeted interventions.

- Demonstrate ROI:By comparing pre- and post-implementation metrics, organizations can quantify the financial benefits of ERP software for maintainability.

- Benchmark against industry standards:Metrics facilitate comparisons with industry benchmarks, highlighting strengths and areas for improvement.

Future Trends in ERP Software for Maintainability

ERP software is continuously evolving to meet the changing needs of businesses. As technology advances, new features and capabilities are being introduced that can further enhance the maintainability of assets.

Some of the key trends that are expected to shape the future of ERP software for maintainability include:

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are rapidly becoming essential technologies for businesses of all sizes. These technologies can be used to automate a wide range of tasks, from data entry to predictive maintenance. In the context of ERP software, AI and ML can be used to:

- Identify and prioritize maintenance tasks

- Predict when equipment is likely to fail

- Generate work orders and schedules

- Track and manage maintenance costs

By automating these tasks, AI and ML can help businesses to improve the efficiency and effectiveness of their maintenance operations.

Cloud-based ERP Systems, ERP software for maintainability

Cloud-based ERP systems are becoming increasingly popular as businesses realize the benefits of moving their software to the cloud. These systems offer a number of advantages over on-premises ERP systems, including:

- Lower costs

- Increased flexibility

- Improved scalability

- Enhanced security

Cloud-based ERP systems can also be easier to maintain than on-premises systems, as the vendor is responsible for managing the infrastructure and software updates.

Vendor Comparison and Selection

When selecting an ERP software vendor for maintainability, it is important to evaluate their expertise, product capabilities, and support offerings.

Consider the following factors when comparing vendors:

- Industry Expertise:Choose a vendor with experience in your industry and a deep understanding of maintenance-related challenges.

- Product Features:Assess the software’s capabilities for managing maintenance work orders, tracking inventory, and providing analytics.

- Support and Training:Ensure the vendor provides comprehensive support, including training, documentation, and ongoing technical assistance.

- Pricing:Compare the total cost of ownership, including licensing fees, implementation costs, and ongoing maintenance.

Vendor Comparison Table

| Vendor | Industry Expertise | Key Features | Support and Training | Pricing |

|---|---|---|---|---|

| Vendor A | Manufacturing, Utilities | Work order management, inventory tracking, predictive analytics | 24/7 support, online training | $50,000

|

| Vendor B | Healthcare, Transportation | Maintenance scheduling, asset tracking, compliance reporting | Business hours support, online documentation | $30,000

|

| Vendor C | Retail, Hospitality | Work order automation, preventive maintenance, mobile access | Limited support, paid training | $20,000

|

Implementation Timeline and Costs

Implementing ERP software for maintainability typically involves a comprehensive process that requires significant planning and resources. The timeline and costs associated with the implementation can vary depending on several factors, including the size and complexity of the organization, the scope of the implementation, and the chosen software solution.

The implementation timeline typically ranges from several months to over a year, depending on the factors mentioned above. The initial phase involves planning and preparation, which includes gathering requirements, selecting the software, and assembling the implementation team. This phase can take several months.

The subsequent phases involve data migration, system configuration, testing, and training. These phases can be time-consuming, especially for large organizations with complex data and processes. The final phase includes go-live and post-implementation support, which can take several months to stabilize the system and ensure smooth operations.

The costs associated with ERP software implementation for maintainability can vary widely depending on the factors discussed earlier. These costs include software licensing fees, implementation services, hardware upgrades, training, and ongoing maintenance and support.

The software licensing fees can range from tens of thousands to millions of dollars, depending on the size and complexity of the organization. Implementation services typically account for a significant portion of the costs, as they involve consulting, data migration, and system configuration.

Hardware upgrades may be necessary to support the new software and data requirements, which can add to the overall costs.

Training costs include both initial training for users and ongoing training to ensure proficiency and adoption. Ongoing maintenance and support costs are essential to keep the system up-to-date, address any issues, and provide ongoing user support.

Ultimate Conclusion

In conclusion, ERP software for maintainability is a transformative tool that empowers organizations to achieve operational excellence. By implementing best practices, organizations can overcome challenges, measure success, and leverage emerging trends to maximize the benefits of ERP software. With its ability to streamline maintenance processes, reduce downtime, and enhance asset utilization, ERP software is the key to unlocking improved maintainability and driving business success.

Quick FAQs

What are the key benefits of using ERP software for maintainability?

ERP software for maintainability offers numerous benefits, including reduced downtime, increased asset utilization, improved compliance, enhanced visibility, and optimized maintenance scheduling.

What are some challenges organizations may face when implementing ERP software for maintainability?

Organizations may encounter challenges such as data integration, change management, cost and resource constraints, and resistance to change when implementing ERP software for maintainability.

How can organizations measure the success of ERP software for maintainability?

Organizations can measure the success of ERP software for maintainability by tracking key performance indicators (KPIs) such as mean time to repair (MTTR), mean time between failures (MTBF), and overall equipment effectiveness (OEE).