ERP software for availability is the cornerstone of modern business operations, providing organizations with the tools they need to track, monitor, and improve availability levels. By leveraging real-time data, analytics, and seamless integration with other systems, ERP systems empower businesses to achieve operational excellence and drive growth.

Throughout this comprehensive guide, we will delve into the intricacies of ERP software for availability, exploring its key features, benefits, and best practices. We will also examine industry-specific considerations and emerging trends, providing you with a holistic understanding of this essential technology.

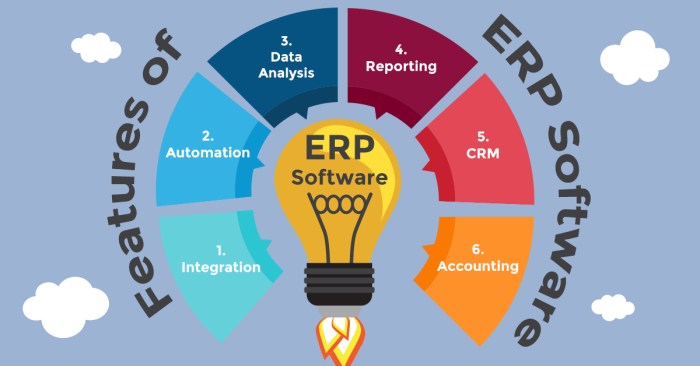

Key Features of ERP Software for Availability

ERP software for availability management offers a range of essential features that enable organizations to optimize their availability planning and execution. These features empower businesses to gain real-time visibility into their inventory, resources, and demand, enabling them to make informed decisions that maximize availability and minimize disruptions.

Inventory Management

Effective inventory management is crucial for ensuring product availability. ERP software provides comprehensive inventory tracking capabilities, including:

- Real-time inventory visibility across multiple locations

- Automated inventory replenishment based on demand forecasts

- Lot and serial number tracking for improved traceability

Resource Planning

ERP software helps organizations optimize resource utilization by providing:

- Capacity planning and scheduling to avoid overbooking and underutilization

- Resource allocation based on skills and availability

- Labor forecasting to anticipate future staffing needs

Demand Forecasting

Accurate demand forecasting is essential for ensuring availability. ERP software offers advanced forecasting capabilities, including:

- Historical data analysis to identify demand patterns

- Machine learning algorithms to predict future demand

- Integration with external data sources to consider market trends

Scenario Planning

ERP software enables organizations to simulate different scenarios and assess their impact on availability. This allows businesses to:

- Identify potential disruptions and develop mitigation plans

- Optimize inventory levels and resource allocation for various demand scenarios

- Evaluate the financial impact of different availability strategies

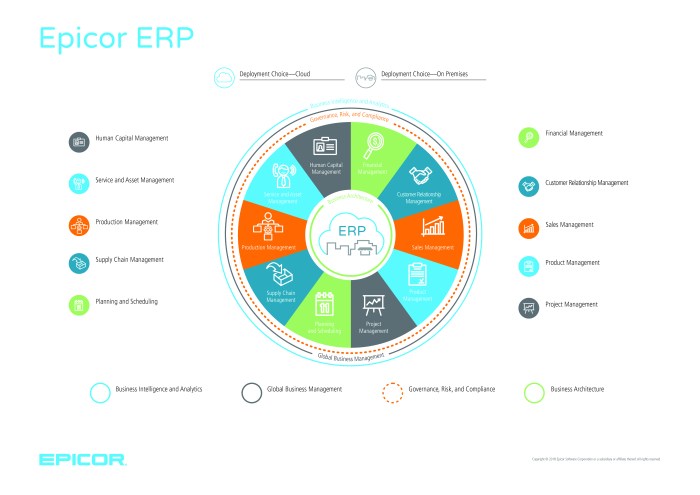

Integration with Other Systems

ERP software for availability integrates with other enterprise systems, such as:

- Supply chain management systems for end-to-end visibility

- Customer relationship management systems for demand insights

- Financial systems for cost analysis and budgeting

This integration enables organizations to access a comprehensive view of their availability-related data and make informed decisions based on real-time information.

Integration with Other Systems

Integrating ERP software with other systems is crucial for maximizing availability by enabling real-time data sharing and streamlined processes.

When ERP systems are integrated with inventory management systems, they can automatically update inventory levels based on sales orders, production schedules, and other relevant data. This integration ensures accurate inventory tracking, reduces stockouts, and improves availability.

Integration with Supply Chain Management Systems

Integrating ERP systems with supply chain management systems streamlines the flow of goods from suppliers to customers. It provides real-time visibility into supplier performance, delivery schedules, and inventory levels. This integration enables proactive management of supply chain disruptions, optimizes inventory levels, and enhances availability by ensuring timely delivery of materials and finished goods.

Real-Time Data and Analytics

Real-time data and analytics play a pivotal role in optimizing availability management. By providing real-time visibility into availability levels, ERP systems empower organizations to make informed decisions and take proactive measures to minimize downtime.

Advanced analytics capabilities enable the identification of trends, patterns, and potential risks. This information can be leveraged to develop predictive maintenance strategies, optimize resource allocation, and improve overall equipment effectiveness.

Data Collection and Visibility

- ERP systems integrate with various sensors and monitoring devices to collect real-time data on equipment performance, environmental conditions, and usage patterns.

- This data is centralized and analyzed to provide a comprehensive view of availability levels across the organization, enabling stakeholders to identify areas for improvement.

Trend Analysis and Predictive Maintenance

- Analytics tools within ERP systems can identify trends and patterns in availability data, helping organizations predict potential issues before they occur.

- This information can be used to develop predictive maintenance schedules, ensuring timely interventions and minimizing the risk of unplanned downtime.

Reporting and Dashboards

Reporting and dashboards are essential tools for availability management. They provide a centralized view of availability data, which can be used to identify trends, patterns, and areas for improvement.Reports can be used to track key metrics such as uptime, downtime, and mean time to repair (MTTR).

Dashboards can provide a visual representation of this data, making it easy to see how availability is trending over time.

Types of Reports and Dashboards

There are many different types of reports and dashboards that can be generated using ERP software. Some of the most common include:* Availability reports:These reports track key availability metrics, such as uptime, downtime, and MTTR.

Trend reports

These reports show how availability is trending over time.

Comparative reports

These reports compare availability across different time periods, locations, or assets.

Executive dashboards

These dashboards provide a high-level overview of availability data.

Operational dashboards

These dashboards provide more detailed information about availability, such as the status of individual assets.

Benefits of Reporting and Dashboards

Reporting and dashboards can provide a number of benefits for availability management, including:* Improved visibility:Reporting and dashboards provide a centralized view of availability data, which can help to improve visibility into the availability of assets.

Early identification of problems

Reporting and dashboards can help to identify problems early on, before they can cause major disruptions.

Informed decision-making

Reporting and dashboards can provide the information needed to make informed decisions about availability management.

Improved communication

Reporting and dashboards can help to improve communication between different stakeholders, such as operations and maintenance teams.

Mobile and Remote Access

In the dynamic business landscape of today, accessing critical information and making timely decisions from anywhere, at any time, has become essential. ERP software for availability management with mobile and remote access capabilities empowers organizations to achieve this.

Mobile apps and remote access features allow authorized users to securely access the ERP system from their smartphones, tablets, or laptops, regardless of their physical location. This real-time connectivity facilitates instant monitoring of availability data, enabling users to respond swiftly to changes and make informed decisions.

Benefits of Mobile and Remote Access

- Enhanced Responsiveness:Mobile access allows users to react immediately to availability issues, minimizing downtime and maximizing equipment utilization.

- Improved Collaboration:Remote access enables seamless communication and collaboration among team members, even when they are not physically present at the same location.

- Increased Productivity:Mobile and remote access eliminates the need for users to be tied to their desks, allowing them to work from anywhere, increasing productivity and flexibility.

Industry-Specific Considerations: ERP Software For Availability

Different industries face unique challenges in managing availability, driven by their specific operating models, regulatory requirements, and customer expectations. ERP software can be tailored to address these industry-specific challenges, ensuring optimal availability management.

Manufacturing

Manufacturers face challenges in maintaining high levels of availability due to complex production processes, fluctuating demand, and supply chain disruptions. ERP software can provide real-time visibility into production schedules, inventory levels, and supplier performance, enabling manufacturers to proactively identify and mitigate potential availability issues.

Healthcare

Healthcare providers must ensure the availability of critical medical equipment, supplies, and staff to deliver timely and effective patient care. ERP software can streamline inventory management, optimize scheduling, and improve communication between departments, enhancing the availability of resources when they are needed most.

Retail

Retailers rely on high availability of products to meet customer demand and minimize lost sales. ERP software can help retailers optimize inventory levels, manage supplier relationships, and forecast demand based on historical data and market trends, ensuring that products are available when and where customers need them.

Case Study: Food and Beverage Industry

A leading food and beverage manufacturer implemented an ERP system to improve availability across its supply chain. The system provided real-time visibility into inventory levels, production schedules, and supplier performance. As a result, the manufacturer reduced lead times by 20%, improved customer service levels by 15%, and reduced inventory carrying costs by 10%.

Implementation and Best Practices

Implementing ERP software for availability management requires careful planning and execution. Here are some guidelines to ensure a successful implementation:

It is crucial to involve stakeholders from all levels of the organization during the implementation process. This includes users, managers, and executives. By involving stakeholders early on, you can gain valuable insights into their needs and requirements, which will help you tailor the ERP system to meet their specific needs.

Best Practices

- Establish a clear implementation plan.This plan should Artikel the project scope, timelines, and resources required. It is important to have a realistic plan that can be executed within the organization’s constraints.

- Engage with a qualified implementation partner.An experienced partner can help you navigate the complexities of ERP implementation and ensure that the system is configured to meet your specific needs.

- Train users thoroughly.Users need to be trained on how to use the ERP system effectively. This training should be tailored to the specific roles and responsibilities of each user.

- Monitor the system regularly.Once the ERP system is implemented, it is important to monitor its performance regularly. This will help you identify any issues that need to be addressed.

Case Studies, ERP software for availability

- Company A:Company A is a large manufacturing company that implemented an ERP system to improve its availability management. The system helped the company to reduce its downtime by 20% and improve its overall efficiency.

- Company B:Company B is a small retail company that implemented an ERP system to improve its inventory management. The system helped the company to reduce its inventory costs by 15% and improve its customer service.

Return on Investment (ROI)

ERP software for availability management can deliver significant ROI by improving efficiency, reducing costs, and increasing revenue.

Factors Contributing to ROI

Improved efficiency

ERP systems automate tasks and streamline processes, reducing labor costs and improving productivity.

Reduced costs

ERP systems help organizations optimize inventory levels, reduce waste, and negotiate better deals with suppliers, leading to cost savings.

Increased revenue

ERP systems provide real-time visibility into demand and inventory levels, enabling organizations to make better decisions about pricing and production, leading to increased sales.

Examples of ROI Achieved

- A manufacturing company implemented an ERP system and achieved a 15% reduction in production costs and a 10% increase in sales.

- A retail company implemented an ERP system and reduced inventory levels by 20%, resulting in a 5% increase in profit margin.

- A healthcare provider implemented an ERP system and reduced patient wait times by 25%, leading to increased patient satisfaction and revenue.

Future Trends in ERP Software for Availability

The future of ERP software for availability management is shaped by emerging trends that enhance efficiency, optimize resource allocation, and improve decision-making.

These trends include the integration of artificial intelligence (AI) and machine learning (ML) for predictive analytics, the adoption of cloud computing for scalability and flexibility, and the development of mobile and remote access capabilities for increased accessibility.

AI and ML for Predictive Analytics

AI and ML algorithms analyze historical data to identify patterns and trends, enabling organizations to predict future demand and availability more accurately.

This allows for proactive planning, optimized resource allocation, and reduced downtime, ultimately improving overall availability and service levels.

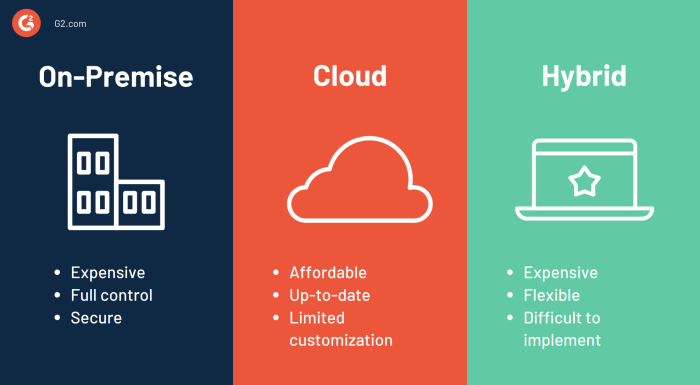

Cloud Computing for Scalability and Flexibility

Cloud-based ERP software provides organizations with the flexibility and scalability to adapt to changing business needs.

With cloud computing, organizations can access the latest software updates and features without the need for costly on-premises infrastructure, reducing maintenance costs and improving overall agility.

Mobile and Remote Access Capabilities

Mobile and remote access capabilities allow users to access ERP software from anywhere, anytime, using smartphones, tablets, or laptops.

This enhances collaboration, facilitates real-time decision-making, and ensures that critical information is available to all stakeholders, regardless of their location.

Summary

In conclusion, ERP software for availability is an indispensable tool for businesses seeking to optimize their operations and maximize uptime. By embracing the power of real-time data, analytics, and seamless integration, organizations can gain unprecedented visibility into their availability levels, identify areas for improvement, and make informed decisions that drive growth and success.

Questions Often Asked

What are the key benefits of using ERP software for availability management?

ERP software for availability management offers numerous benefits, including improved visibility into availability levels, reduced downtime, increased productivity, enhanced customer satisfaction, and optimized resource allocation.

How does ERP software integrate with other systems to improve availability?

ERP software seamlessly integrates with inventory management, supply chain management, and other systems to provide a comprehensive view of availability across the entire organization. This integration enables real-time data sharing, automated processes, and improved coordination, leading to enhanced availability.

What are the best practices for implementing ERP software for availability management?

Best practices for implementing ERP software for availability management include defining clear goals, involving stakeholders, choosing the right software, ensuring data accuracy, and providing ongoing training and support.