ERP software for supplier relationship management (SRM) has emerged as a transformative tool, redefining the way businesses connect with their suppliers. By harnessing the power of technology, organizations can streamline processes, enhance collaboration, and drive operational excellence.

In this comprehensive guide, we will delve into the intricacies of ERP software for SRM, exploring its key features, quantifying its benefits, and providing practical insights into its successful implementation. Join us as we unlock the potential of this innovative solution and empower your business to forge stronger, more profitable supplier relationships.

ERP Software for Supplier Relationship Management (SRM)

ERP software can provide several benefits for supplier relationship management (SRM), including:

- Improved visibility into supplier performance

- Enhanced communication and collaboration with suppliers

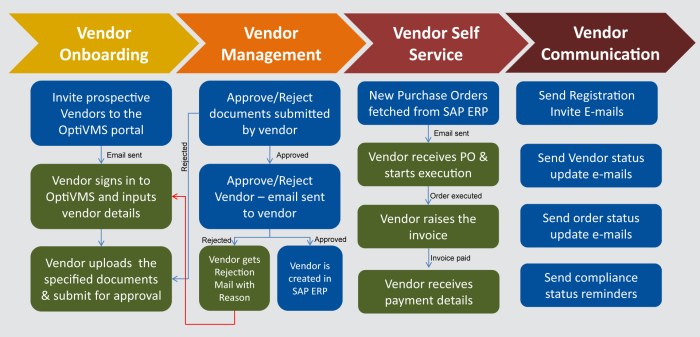

- Streamlined supplier onboarding and management

- Reduced costs and improved efficiency

- Increased compliance and risk management

However, there are also some challenges associated with implementing ERP software for SRM, such as:

- The cost of implementation

- The complexity of the software

- The need for change management

- The potential for disruption to business operations

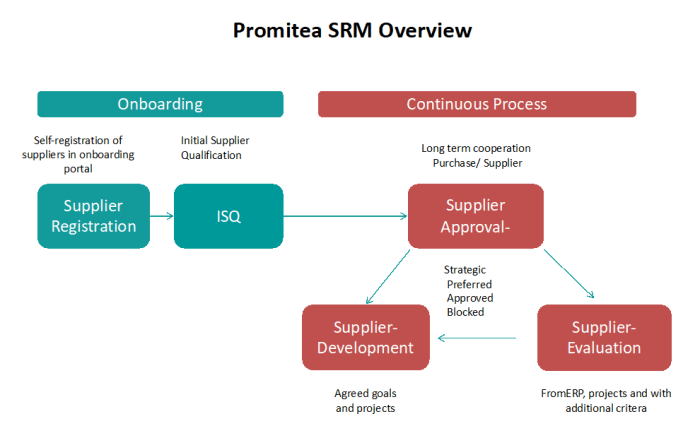

Despite these challenges, ERP software can be a valuable tool for improving supplier relationships. By providing a single, integrated platform for managing all aspects of the supplier lifecycle, ERP software can help businesses to:

- Identify and qualify new suppliers

- Negotiate and manage contracts

- Monitor supplier performance

- Develop and implement supplier improvement plans

- Reduce costs and improve efficiency

Here are some examples of how ERP software can be used to improve supplier relationships:

- A manufacturing company can use ERP software to track supplier performance, identify potential risks, and develop supplier improvement plans.

- A retail company can use ERP software to manage contracts, streamline supplier onboarding, and improve communication with suppliers.

- A healthcare provider can use ERP software to ensure compliance with regulatory requirements, manage supplier risk, and improve patient safety.

Features of ERP Software for SRM: ERP Software For Supplier Relationship Management

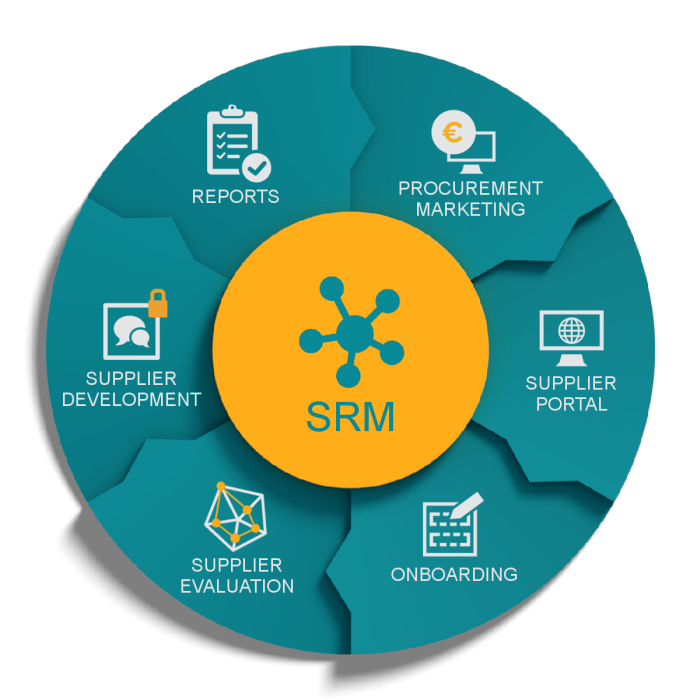

ERP software for supplier relationship management (SRM) offers a comprehensive suite of features to enhance collaboration, streamline processes, and improve visibility within the supply chain.

Core features of ERP software for SRM include:

- Supplier onboarding and management

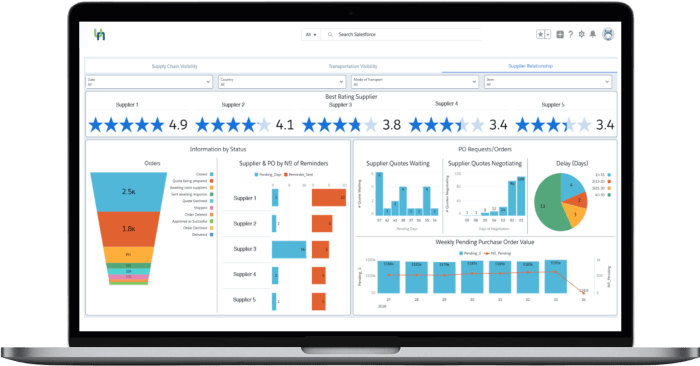

- Supplier performance monitoring

- Supplier risk management

- Collaboration and communication tools

- Data analytics and reporting

Comparison of ERP Software Vendors

Different ERP software vendors offer varying capabilities within their SRM modules. It is essential to compare the features of different vendors to determine the best fit for an organization’s specific needs.

Key factors to consider when comparing ERP software vendors include:

- Functionality: Assess the breadth and depth of the SRM features offered.

- Integration: Determine the ease of integration with existing systems and applications.

- Scalability: Consider the software’s ability to support future growth and expansion.

- Cost: Evaluate the total cost of ownership, including licensing, implementation, and maintenance.

- Vendor reputation: Research the vendor’s track record, customer satisfaction ratings, and industry expertise.

Key Features of ERP Software for SRM

The following table summarizes the key features of ERP software for SRM:

| Feature | Description |

|---|---|

| Supplier onboarding and management | Streamline the process of adding new suppliers to the system, managing supplier data, and maintaining supplier relationships. |

| Supplier performance monitoring | Track and evaluate supplier performance based on predefined metrics, such as delivery time, quality, and cost. |

| Supplier risk management | Identify and mitigate potential risks associated with suppliers, including financial stability, operational capabilities, and compliance issues. |

| Collaboration and communication tools | Provide a central platform for collaboration between buyers and suppliers, enabling easy communication and file sharing. |

| Data analytics and reporting | Generate reports and insights into supplier performance, risk, and collaboration, helping organizations make informed decisions. |

Benefits of Using ERP Software for SRM

ERP software for supplier relationship management (SRM) offers numerous benefits to businesses, including improved supplier performance, reduced costs, and increased efficiency.

By automating and streamlining the supplier management process, ERP software can help businesses to reduce the time and effort required to manage supplier relationships. This can lead to significant cost savings, as well as improved supplier performance and efficiency.

Quantifying the Benefits of Using ERP Software for SRM

The benefits of using ERP software for SRM can be quantified in a number of ways. For example, a study by Aberdeen Group found that businesses that use ERP software for SRM experience an average of:

- 15% reduction in supplier costs

- 10% improvement in supplier performance

- 5% increase in efficiency

ROI of Implementing ERP Software for SRM

The ROI of implementing ERP software for SRM can be significant. A study by Gartner found that businesses that implement ERP software for SRM can expect to see a return on investment of 200% or more.

Case Studies of Companies That Have Successfully Implemented ERP Software for SRM

There are many case studies of companies that have successfully implemented ERP software for SRM. For example, the Coca-Cola Company implemented ERP software for SRM in 2006. Since then, the company has seen a 15% reduction in supplier costs and a 10% improvement in supplier performance.

Best Practices for Using ERP Software for SRM

To effectively leverage ERP software for supplier relationship management (SRM), it is essential to adopt best practices that optimize its capabilities and maximize its benefits. These practices include:

Data Management, ERP software for supplier relationship management

Data is the foundation of effective SRM. ERP software provides a centralized platform for collecting, storing, and managing supplier data, including contact information, performance metrics, and financial data. It is crucial to ensure data accuracy and completeness to support informed decision-making and supplier evaluations.

Supplier Performance Management

ERP software enables the tracking and management of supplier performance. By establishing key performance indicators (KPIs) and regularly monitoring supplier performance against these metrics, businesses can identify areas for improvement and foster continuous improvement. ERP systems can automate data collection, generate performance reports, and provide insights for data-driven decision-making.

Collaboration and Communication

ERP software facilitates collaboration and communication between businesses and their suppliers. It provides a platform for sharing information, exchanging documents, and managing supplier interactions. By enhancing communication and fostering transparency, ERP systems promote stronger supplier relationships and improve coordination.

Supplier Risk Management

ERP software can assist in managing supplier risk by providing a comprehensive view of supplier information. Businesses can use this data to assess supplier financial stability, compliance with regulations, and potential vulnerabilities. By proactively identifying and mitigating supplier risks, ERP systems help ensure supply chain resilience and business continuity.

Continuous Improvement

ERP software supports continuous improvement by providing data and insights that enable businesses to identify areas for optimization. By analyzing supplier performance, identifying bottlenecks, and exploring new opportunities, businesses can continuously enhance their SRM processes and drive value from their supplier relationships.

Closing Notes

As we conclude our exploration of ERP software for SRM, it is evident that this technology has become an indispensable asset for businesses seeking to optimize their supply chains and drive growth. By embracing its capabilities, organizations can unlock a world of possibilities, transforming their supplier relationships into strategic partnerships that drive innovation, efficiency, and competitive advantage.

We encourage you to take the next step in your SRM journey by implementing ERP software tailored to your specific needs. Embrace the power of technology and witness the transformative impact it can have on your business.

Questions Often Asked

What are the key benefits of using ERP software for SRM?

ERP software for SRM offers numerous benefits, including improved collaboration, streamlined processes, enhanced visibility, reduced costs, and increased compliance.

What are the challenges of implementing ERP software for SRM?

Common challenges include data integration, user adoption, process alignment, and organizational resistance. However, with proper planning and execution, these challenges can be effectively overcome.

How can ERP software be used to improve supplier relationships?

ERP software facilitates better communication, enhances collaboration, provides real-time visibility, and enables data-driven decision-making, all of which contribute to stronger supplier relationships.