ERP software for digital twin is revolutionizing the way businesses manage and optimize their operations. By integrating ERP data with digital twin technology, organizations gain a comprehensive view of their physical assets, processes, and systems, enabling them to make data-driven decisions and improve overall performance.

This integration provides a real-time, virtual representation of physical assets, allowing businesses to monitor, simulate, and optimize their operations remotely. ERP software serves as the central hub for data collection, providing a single source of truth for all relevant information.

Introduction to ERP Software for Digital Twin

ERP software plays a vital role in digital twin technology by providing a centralized platform for managing and integrating data from various sources. This data includes product design, manufacturing processes, and operational information. By leveraging ERP software, organizations can create a comprehensive digital twin that accurately reflects the physical asset or system.

Benefits of Using ERP Software for Digital Twin Implementation

Utilizing ERP software for digital twin implementation offers numerous advantages, including:

- Improved data accuracy and consistency: ERP software ensures that all data used to create the digital twin is accurate and consistent, eliminating discrepancies and errors.

- Enhanced collaboration and communication: ERP software facilitates collaboration among different teams involved in the digital twin project, enabling seamless communication and knowledge sharing.

- Increased efficiency and productivity: By automating tasks and streamlining processes, ERP software improves efficiency and productivity throughout the digital twin lifecycle.

- Reduced costs and risks: ERP software helps organizations reduce costs associated with digital twin development and implementation, while mitigating risks by providing a reliable and secure platform.

- Improved decision-making: ERP software provides real-time data and insights that empower decision-makers to make informed decisions based on accurate information.

Key Features of ERP Software for Digital Twin

ERP software for digital twin integrates essential features that empower digital twin capabilities. These features enable seamless data exchange, real-time monitoring, and advanced analytics, enhancing the overall effectiveness of digital twins.

Key features of ERP software for digital twin include:

Data Integration and Exchange

- ERP systems provide a central platform for data integration, connecting various data sources and ensuring data consistency across the organization.

- This enables the seamless flow of data between physical assets, digital twins, and other enterprise systems, facilitating real-time updates and comprehensive insights.

Real-Time Monitoring and Control

- ERP software enables real-time monitoring of physical assets and their digital twins, providing a comprehensive view of asset performance and health.

- This allows for proactive maintenance, predictive analytics, and remote control of assets, optimizing operational efficiency and minimizing downtime.

Advanced Analytics and Reporting

- ERP software offers robust analytics capabilities, enabling the analysis of data from physical assets and digital twins to identify patterns, trends, and anomalies.

- This empowers organizations to make data-driven decisions, improve asset utilization, and enhance overall operational performance.

Simulation and Modeling

- ERP software can integrate with simulation and modeling tools, allowing organizations to create virtual representations of physical assets and processes.

- This enables the testing of different scenarios, optimization of asset performance, and the identification of potential issues before they occur.

Collaboration and Communication

- ERP software facilitates collaboration and communication among various stakeholders involved in digital twin initiatives.

- It provides a central platform for sharing information, tracking progress, and ensuring alignment across teams.

Benefits of Using ERP Software for Digital Twin

ERP software integrated with digital twin technology offers numerous advantages for businesses. By combining real-time data from physical assets with enterprise-wide information, organizations can gain valuable insights and make informed decisions.One of the key benefits is improved operational efficiency. ERP software provides a central platform for managing all aspects of business operations, including production, inventory, and supply chain.

When integrated with a digital twin, this data can be used to optimize processes, reduce waste, and increase productivity. For example, a manufacturing company can use a digital twin of its production line to identify bottlenecks and implement improvements that increase output.Another benefit is enhanced product quality.

Digital twins allow businesses to simulate different scenarios and test changes before implementing them in the physical world. This helps to reduce the risk of defects and improve the overall quality of products. For example, a car manufacturer can use a digital twin to test different designs and configurations before committing to production, ensuring that the final product meets the desired specifications.Furthermore, ERP software integrated with digital twin technology can lead to reduced costs.

By optimizing operations and improving product quality, businesses can reduce waste and increase efficiency, resulting in lower production costs. Additionally, the ability to simulate different scenarios can help businesses avoid costly mistakes and make more informed investment decisions. For example, a construction company can use a digital twin to simulate different construction methods and materials to determine the most cost-effective approach.

Case Study: Automotive Industry

A leading automotive manufacturer implemented an ERP system integrated with digital twin technology to improve its production efficiency. The digital twin provided real-time data on the status of each vehicle on the assembly line, allowing the company to identify and address bottlenecks.

As a result, the manufacturer was able to reduce production time by 15% and increase output by 10%.

Case Study: Healthcare Industry

A hospital implemented an ERP system integrated with digital twin technology to improve patient care. The digital twin provided real-time data on the location and status of patients, medical equipment, and staff. This allowed the hospital to optimize patient flow, reduce wait times, and improve the overall efficiency of its operations.

As a result, the hospital was able to increase patient satisfaction and reduce operating costs.

Challenges of Implementing ERP Software for Digital Twin

Implementing ERP software for digital twin can present certain challenges. Understanding and addressing these challenges is crucial for ensuring a successful integration.

One challenge lies in the complexity of integrating ERP systems with digital twin technology. Digital twins require real-time data from various sources, which can be challenging to integrate with existing ERP systems. Data compatibility and data quality issues can also arise, requiring careful data mapping and cleansing.

Data Integration

Integrating ERP data with digital twin models requires careful planning and execution. Data inconsistencies, data redundancy, and data latency can hinder the effective use of digital twins. Establishing clear data governance policies and implementing data integration tools can help overcome these challenges.

Security Concerns

Digital twins often contain sensitive data, making security a critical concern. ERP systems must be properly configured to ensure data privacy and integrity. Implementing robust security measures, such as encryption, access controls, and regular security audits, is essential.

Change Management

Implementing ERP software for digital twin can involve significant changes to existing processes and workflows. Managing these changes effectively is crucial to ensure user adoption and minimize disruptions. Clear communication, training, and support are essential for a smooth transition.

Best Practices for ERP Software Implementation for Digital Twin

Implementing ERP software for digital twin projects requires careful planning and execution to ensure successful outcomes. Here are some best practices to consider:

- Selecting the Right Software:Choose an ERP solution that aligns with the specific requirements of the digital twin project. Consider factors such as industry-specific functionality, scalability, and integration capabilities.

- Phased Implementation:Break down the implementation process into manageable phases to minimize disruptions and ensure a smooth transition. This allows for iterative testing and feedback gathering, ensuring the system meets the desired outcomes.

- Data Integration:Establish a comprehensive data integration strategy to ensure seamless data flow between the ERP system and other digital twin components. This includes defining data standards, mapping data fields, and implementing data transformation processes.

- User Training and Adoption:Provide thorough training to users on the ERP system’s functionality and best practices. Ensure users understand the benefits and value of the system to drive adoption and maximize its effectiveness.

- Continuous Improvement:Establish a process for ongoing monitoring, evaluation, and improvement of the ERP system. Regularly assess its performance, identify areas for optimization, and implement enhancements to ensure it remains aligned with the evolving needs of the digital twin project.

Integration of ERP Software with Digital Twin Platforms

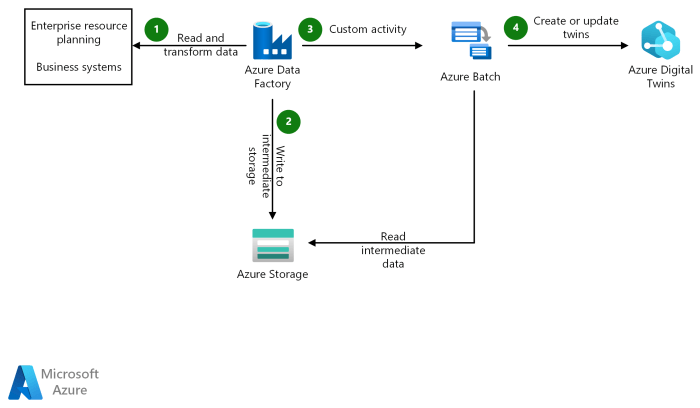

ERP software and digital twin platforms can be integrated using various methods. These methods include data exchange protocols, application programming interfaces (APIs), and middleware.

Data exchange protocols enable the direct exchange of data between ERP software and digital twin platforms. Common data exchange protocols include OPC UA, MQTT, and AMQP.

APIs provide a standardized interface for integrating ERP software with digital twin platforms. APIs allow ERP software to access and modify data in digital twin platforms, and vice versa.

Middleware is software that facilitates the integration of ERP software with digital twin platforms. Middleware can translate data between different data formats, route data between different systems, and provide security.

Integration Architectures

There are two main integration architectures for ERP software and digital twin platforms: tight integration and loose integration.

Tight integration involves creating a direct connection between ERP software and digital twin platforms. This type of integration requires significant development effort, but it provides the highest level of data integrity and performance.

Loose integration involves using middleware to connect ERP software and digital twin platforms. This type of integration is less complex to implement, but it may result in lower data integrity and performance.

Use Cases of ERP Software for Digital Twin

ERP software for digital twins finds applications in various industries, enhancing digital twin capabilities and enabling data-driven decision-making. Here are some prominent use cases:

Manufacturing

- Product Lifecycle Management:ERP software integrates with digital twins to track product data throughout the lifecycle, from design to production and maintenance.

- Production Planning and Scheduling:Real-time data from digital twins helps ERP systems optimize production schedules, identify bottlenecks, and improve efficiency.

- Predictive Maintenance:Digital twins monitor equipment performance and predict maintenance needs, enabling proactive maintenance and reducing downtime.

Supply Chain Management, ERP software for digital twin

- Inventory Optimization:Digital twins provide real-time inventory data, enabling ERP systems to optimize inventory levels and reduce waste.

- Logistics Planning:ERP software uses digital twin data to optimize logistics operations, such as route planning and transportation scheduling.

- Supplier Collaboration:Digital twins facilitate collaboration between manufacturers and suppliers, providing visibility into production and inventory data.

Healthcare

- Patient Monitoring:Digital twins of patients can monitor vital signs, track treatment progress, and identify potential complications.

- Surgical Planning:Digital twins of surgical procedures allow surgeons to simulate and plan surgeries, reducing risks and improving outcomes.

- Drug Development:Digital twins of biological systems help researchers model drug interactions and predict drug efficacy.

Future Trends in ERP Software for Digital Twin

ERP software for digital twin technology is continuously evolving, driven by advancements in artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT). These emerging trends are shaping the future of ERP software and its integration with digital twin platforms.

AI and ML for Enhanced Data Analysis and Decision-Making

AI and ML algorithms are being integrated into ERP software to improve data analysis capabilities. These algorithms can process vast amounts of data from digital twins and other sources, identifying patterns, anomalies, and insights that would be difficult to detect manually.

This enhanced data analysis empowers businesses to make informed decisions, optimize operations, and predict future outcomes with greater accuracy.

IoT Integration for Real-Time Data Collection and Monitoring

IoT devices are becoming increasingly prevalent in industrial settings, providing real-time data on equipment performance, environmental conditions, and other operational parameters. ERP software is integrating with IoT platforms to capture and analyze this data, creating a comprehensive view of the physical world and its digital representation.

This real-time data enables businesses to monitor operations remotely, identify potential issues early on, and make proactive adjustments to improve efficiency and reduce downtime.

Cloud Computing for Scalability and Accessibility

Cloud computing is gaining popularity for ERP software deployments, offering scalability, flexibility, and cost-effectiveness. Cloud-based ERP systems can be easily scaled up or down to meet changing business needs, and they can be accessed from anywhere with an internet connection.

This accessibility allows businesses to collaborate more effectively and make data-driven decisions from any location.

Digital Twin Interoperability for Seamless Data Exchange

Interoperability between different digital twin platforms is becoming increasingly important as businesses adopt multiple digital twin solutions for different purposes. ERP software is playing a crucial role in facilitating data exchange between these platforms, ensuring that data is consistent and accessible across the enterprise.

This interoperability enables businesses to create a holistic digital representation of their operations and make informed decisions based on a comprehensive view of their physical assets and processes.

Blockchain for Secure Data Management and Transparency

Blockchain technology is being explored for use in ERP software for digital twin to enhance data security and transparency. Blockchain provides a decentralized and immutable ledger system that can securely store and track data related to digital twins. This technology can help businesses ensure the integrity of their data and build trust among stakeholders by providing a transparent and verifiable record of transactions and interactions.

Comparison of ERP Software for Digital Twin

ERP software solutions designed for digital twin integration offer a range of features and benefits to meet the unique requirements of different industries and use cases. To help organizations make informed decisions, a comparative analysis of leading ERP software solutions is presented below.

Key Features and Benefits

The following table summarizes the key features and benefits of different ERP software solutions for digital twin integration:

| Feature | Vendor 1 | Vendor 2 | Vendor 3 |

|---|---|---|---|

| Digital Twin Integration | Real-time data exchange | Automated data synchronization | Bi-directional communication |

| Manufacturing Execution (MES) | Production planning and scheduling | Quality control and monitoring | Equipment maintenance and optimization |

| Supply Chain Management (SCM) | Inventory management | Supplier collaboration | Logistics and transportation |

| Enterprise Asset Management (EAM) | Asset tracking and maintenance | Predictive analytics | Compliance management |

| Benefits | Improved decision-making | Increased efficiency | Reduced costs |

Pricing Information

Pricing for ERP software solutions for digital twin integration varies depending on factors such as the number of users, the number of modules required, and the level of support needed. Here is a general overview of pricing information for the vendors listed above:

- Vendor 1: $10,000 – $100,000 per year

- Vendor 2: $5,000 – $50,000 per year

- Vendor 3: $15,000 – $150,000 per year

Conclusive Thoughts

In conclusion, ERP software for digital twin empowers businesses to achieve operational excellence. By leveraging the combined capabilities of ERP and digital twin technology, organizations can enhance decision-making, optimize resource allocation, and drive innovation.

Key Questions Answered

What are the benefits of using ERP software for digital twin?

ERP software provides a central hub for data collection, enabling real-time monitoring, simulation, and optimization of physical assets and processes.

How does ERP software integrate with digital twin platforms?

ERP software can integrate with digital twin platforms through various methods, including data exchange protocols and integration architectures.

What are some industry-specific use cases for ERP software with digital twin?

ERP software with digital twin finds applications in various industries, such as manufacturing, supply chain management, and healthcare.