ERP software for engineer-to-order manufacturing takes center stage, offering a transformative solution that streamlines complex processes, enhances collaboration, and empowers businesses to meet the unique demands of ETO environments.

With its specialized capabilities, ERP software seamlessly integrates design, engineering, and manufacturing operations, ensuring accuracy, efficiency, and timely delivery.

Key Features of ERP Software for Engineer-to-Order Manufacturing

Engineer-to-order (ETO) manufacturing is a production process where products are designed and manufactured based on specific customer requirements. Unlike mass production, ETO involves a high degree of customization and flexibility, making it essential to have an ERP system that can streamline and support the unique processes involved.

ERP software for ETO manufacturing provides a comprehensive suite of tools and modules tailored to the specific needs of this industry. These systems offer features that help manage the entire product lifecycle, from design and engineering to production, delivery, and售后服务.

By integrating all aspects of the business into a single platform, ERP systems for ETO manufacturing can significantly improve efficiency, reduce costs, and enhance customer satisfaction.

Core Modules and Capabilities

The core modules and capabilities of ERP software for ETO manufacturing include:

- Product Configurator:Allows engineers to quickly and easily configure products based on customer specifications, ensuring accuracy and reducing the risk of errors.

- Engineering Change Management:Provides tools to manage and track engineering changes throughout the product lifecycle, ensuring that all stakeholders are informed and that changes are implemented smoothly.

- Production Planning and Scheduling:Helps manufacturers plan and schedule production based on customer orders, taking into account resource availability, lead times, and other constraints.

- Materials Management:Manages the procurement and inventory of raw materials and components, ensuring that the right materials are available at the right time.

- Quality Control:Provides tools to manage and track quality control processes, ensuring that products meet customer specifications and regulatory requirements.

- Customer Relationship Management (CRM):Manages customer interactions, including order processing, quoting, and售后服务, providing a complete view of customer history and preferences.

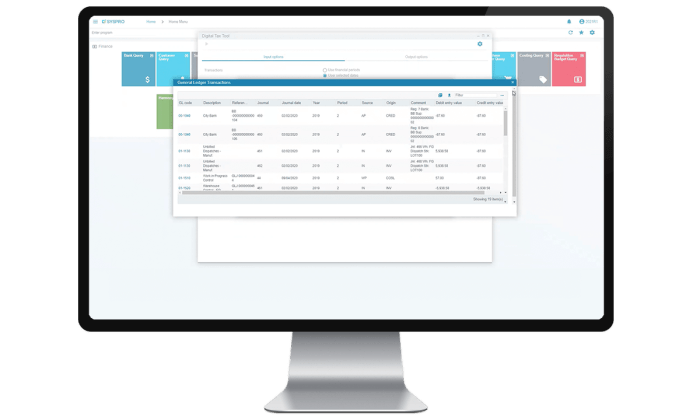

- Financial Management:Provides tools to manage financial transactions, including invoicing, accounts receivable, and accounts payable, ensuring accurate and timely financial reporting.

Benefits of Implementing ERP Software for ETO Manufacturing

ERP software offers numerous advantages for ETO manufacturers, significantly enhancing their operations and business outcomes. These benefits encompass cost savings, efficiency gains, improved collaboration, enhanced customer satisfaction, and reduced lead times.

Quantifying Cost Savings and Efficiency Gains

ERP systems streamline processes, eliminate redundancies, and automate tasks, leading to substantial cost reductions. They provide real-time visibility into production schedules, inventory levels, and resource allocation, enabling manufacturers to optimize operations and minimize waste. Additionally, ERP software reduces the need for manual data entry and reconciliation, saving time and reducing errors.

Enhancing Collaboration and Communication

ERP software serves as a central platform for all departments within an ETO manufacturing organization, facilitating seamless communication and collaboration. It provides a shared view of data, eliminating silos and ensuring that everyone has access to the most up-to-date information.

This improved communication and collaboration enable faster decision-making and better coordination, leading to increased productivity and efficiency.

Improving Customer Satisfaction and Reducing Lead Times

By integrating all aspects of the manufacturing process into a single system, ERP software enables ETO manufacturers to respond more quickly to customer inquiries and orders. The improved visibility and coordination provided by ERP reduce lead times, allowing manufacturers to deliver products faster and meet customer expectations.

Furthermore, ERP software enhances customer satisfaction by providing accurate and timely information on order status, delivery dates, and product availability.

Challenges of Implementing ERP Software for ETO Manufacturing

ERP software implementation for engineer-to-order (ETO) manufacturing poses unique challenges due to the complexities of the manufacturing process. The integration of disparate data sources and the need for extensive customization can be a significant hurdle. Moreover, resistance to change and user adoption issues can arise due to the disruption of established workflows.

Data Integration and Customization

ETO manufacturing involves a high degree of customization, which requires the ERP system to be flexible enough to accommodate the diverse requirements of each project. Integrating data from various sources, such as CAD/CAM systems, engineering change orders, and supplier networks, can be a complex task.

Additionally, customizing the ERP system to meet the specific needs of the ETO manufacturer can be time-consuming and resource-intensive.

Resistance to Change and User Adoption

Implementing an ERP system can disrupt established workflows and processes, leading to resistance from users. The adoption of new software requires training, support, and a change in mindset. Overcoming resistance to change and ensuring user buy-in is crucial for successful implementation.

Robust Training and Support

The complexity of ERP software for ETO manufacturing necessitates robust training and support. Users need to be thoroughly trained on the system’s functionality and how it aligns with their daily tasks. Ongoing support is also essential to address any issues or challenges that may arise during and after implementation.

Vendor Evaluation and Selection

Selecting the right ERP vendor is critical for the success of an ETO manufacturing implementation. Here’s a framework to help you evaluate and select vendors:

Industry-Specific Experience and References

ETO manufacturing is a unique industry with specific requirements. Look for vendors who have experience implementing ERP solutions in ETO environments. Ask for references from existing customers in your industry to gauge their satisfaction with the vendor’s solution and services.

Factors to Consider When Comparing Solutions

When comparing different ERP solutions, consider the following factors:

- Functionality:Ensure the solution meets your specific ETO manufacturing requirements, including product configuration, engineering change management, and project management.

- Integration:Assess how well the solution integrates with your existing systems, such as CAD/CAM, CRM, and supply chain management.

- Scalability:Consider the future growth of your business and ensure the solution can scale to meet your evolving needs.

- Cost:Determine the total cost of ownership, including implementation, maintenance, and support.

- Support:Evaluate the vendor’s level of support, including response times, documentation, and training.

Case Studies and Success Stories

ERP software implementations in engineer-to-order (ETO) manufacturing have yielded remarkable benefits and outcomes for various organizations. Let’s explore some notable case studies and success stories:

ABB

- ABB, a global leader in power and automation technologies, implemented an ERP system to streamline its ETO manufacturing operations.

- The system enabled ABB to achieve a 25% reduction in order lead times and a 15% increase in production efficiency.

- “The ERP system has been a game-changer for our ETO manufacturing. It has given us the agility and efficiency we need to meet the unique demands of our customers,” said a senior executive at ABB.

Siemens

- Siemens, a multinational conglomerate specializing in electronics and electrical engineering, deployed an ERP solution to enhance its ETO manufacturing capabilities.

- The implementation resulted in a 30% reduction in product development costs and a 20% increase in customer satisfaction.

- “The ERP system has enabled us to integrate our engineering and manufacturing processes, leading to significant cost savings and improved customer responsiveness,” said a Siemens spokesperson.

Caterpillar

- Caterpillar, a leading manufacturer of construction and mining equipment, implemented an ERP system to optimize its ETO manufacturing operations.

- The system helped Caterpillar achieve a 10% increase in engineering productivity and a 15% reduction in material waste.

- “The ERP system has transformed our ETO manufacturing processes. It has provided us with the tools we need to deliver high-quality products to our customers efficiently,” said a Caterpillar manager.

Emerging Trends and Future Outlook

The ERP landscape for ETO manufacturing is constantly evolving, driven by technological advancements and industry demands. The latest advancements in ERP technology, such as cloud computing, artificial intelligence (AI), and machine learning (ML), are transforming the way ETO businesses operate.

AI and ML algorithms can analyze vast amounts of data to identify patterns, predict outcomes, and optimize processes. This enables ETO businesses to gain real-time insights into their operations, make data-driven decisions, and improve overall efficiency.

Future Trends and Implications, ERP software for engineer-to-order manufacturing

As technology continues to advance, we can expect to see even more innovative applications of ERP technology in ETO manufacturing. These include:

- Increased automation:AI and ML will drive further automation of repetitive tasks, freeing up engineers to focus on more complex and value-added activities.

- Enhanced collaboration:Cloud-based ERP systems will facilitate seamless collaboration between engineering, manufacturing, and sales teams, enabling real-time information sharing and improved coordination.

- Personalized experiences:AI-powered ERP systems will provide personalized experiences for customers, allowing them to track the progress of their orders, access product information, and receive tailored recommendations.

- Predictive analytics:Advanced analytics capabilities will enable ETO businesses to predict future demand, optimize inventory levels, and make informed decisions about product development and marketing strategies.

These emerging trends have the potential to revolutionize ETO manufacturing, enabling businesses to achieve greater efficiency, agility, and customer satisfaction.

Return on Investment (ROI)

ERP software for engineer-to-order (ETO) manufacturing offers substantial return on investment (ROI) by optimizing processes, reducing costs, and improving efficiency. The benefits of implementing ERP software extend beyond cost savings, leading to strategic advantages that enhance competitiveness.

Cost Savings and Efficiency Gains

- Reduced material waste and inventory costs through improved planning and forecasting.

- Optimized production processes, leading to reduced labor costs and improved productivity.

- Streamlined communication and collaboration, minimizing delays and rework.

Long-Term Benefits and Strategic Advantages

- Improved customer satisfaction through faster order fulfillment and reduced errors.

- Increased agility and responsiveness to changing market demands.

- Enhanced data visibility and decision-making capabilities, leading to better resource allocation.

Additional Considerations

When implementing ERP software for ETO manufacturing, it is crucial to consider several additional factors to ensure a successful and sustainable deployment.

These considerations include:

Data Security and Compliance

Protecting sensitive data is paramount in ETO manufacturing, where confidential designs and customer information are often involved. ERP systems must comply with industry regulations and standards, such as ISO 27001 and HIPAA, to safeguard data from unauthorized access, breaches, and cyber threats.

Ongoing Maintenance and Support

ERP software requires regular maintenance and support to ensure optimal performance and address any technical issues that may arise. This includes software updates, bug fixes, and technical assistance from the vendor or a third-party provider.

Cloud-Based ERP Solutions

Cloud-based ERP solutions offer several benefits for ETO manufacturers, including:

- Scalability: Cloud-based ERP systems can easily scale up or down to meet changing business needs, providing flexibility and cost-effectiveness.

- Accessibility: Cloud-based ERP systems are accessible from anywhere with an internet connection, allowing for remote work and collaboration.

- Reduced IT Infrastructure Costs: Cloud-based ERP solutions eliminate the need for on-premises servers and IT infrastructure, reducing capital and maintenance costs.

Last Word: ERP Software For Engineer-to-order Manufacturing

As the future unfolds, ERP software for ETO manufacturing will continue to evolve, driven by advancements in technology and the increasing need for customization and agility. Embracing these solutions will empower ETO businesses to stay competitive, drive innovation, and achieve operational excellence.

FAQ Guide

What are the key benefits of ERP software for ETO manufacturing?

ERP software streamlines processes, improves collaboration, reduces lead times, and enhances customer satisfaction.

What are the challenges of implementing ERP software for ETO manufacturing?

Challenges include data integration, change management, and the need for robust training and support.

How can I evaluate ERP vendors for ETO manufacturing?

Consider industry-specific experience, references, and the alignment of their solutions with your business requirements.