In the realm of manufacturing, ERP software for assemble-to-order manufacturing stands as a transformative solution, streamlining operations and empowering businesses to achieve new heights of efficiency and profitability. This specialized software caters to the unique needs of assemble-to-order environments, where products are tailored to meet specific customer requirements.

With its comprehensive suite of features and functionalities, ERP software orchestrates every aspect of assemble-to-order manufacturing, from production planning and scheduling to inventory management and customer relationship management. By integrating these functions into a single, unified platform, ERP software eliminates inefficiencies, improves data accuracy, and fosters seamless collaboration across the enterprise.

Overview of ERP Software for Assemble-to-Order Manufacturing

ERP software is a critical tool for assemble-to-order (ATO) manufacturers. It provides the real-time visibility and control necessary to manage the complex processes involved in ATO manufacturing, from order entry to production scheduling to inventory management.

Key benefits of ERP software for ATO manufacturers include:

- Improved order accuracy and fulfillment

- Reduced lead times

- Increased inventory visibility and control

- Improved production efficiency

- Reduced costs

ERP systems designed for ATO environments typically include the following key features and functionalities:

Order Management

The order management module allows manufacturers to manage the entire order lifecycle, from order entry to fulfillment. It provides real-time visibility into order status, inventory availability, and production schedules.

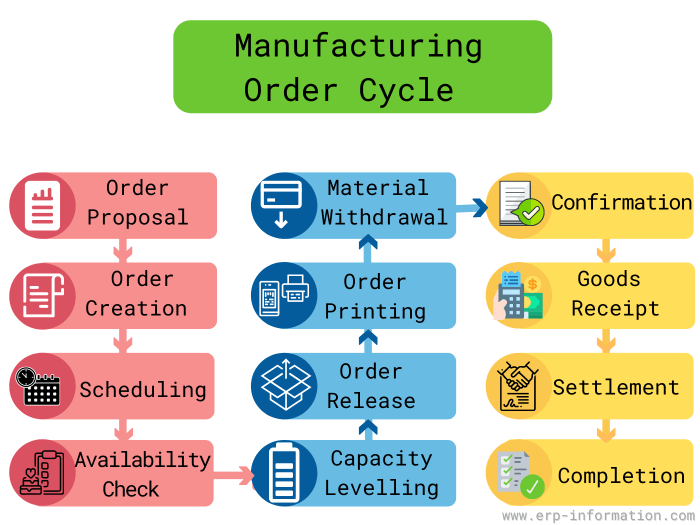

Production Planning and Scheduling

The production planning and scheduling module helps manufacturers plan and schedule production orders based on customer demand, inventory levels, and production capacity. It ensures that orders are produced on time and in the correct sequence.

Inventory Management, ERP software for assemble-to-order manufacturing

The inventory management module provides real-time visibility into inventory levels and helps manufacturers manage inventory levels to meet customer demand while minimizing carrying costs.

Materials Management

The materials management module helps manufacturers manage the procurement of raw materials and components. It provides real-time visibility into supplier performance, inventory levels, and purchase orders.

Quality Control

The quality control module helps manufacturers manage the quality of their products. It provides real-time visibility into quality control processes and helps manufacturers identify and correct quality issues.

Benefits of ERP Software for Assemble-to-Order Manufacturing

ERP software offers significant benefits for assemble-to-order manufacturers, streamlining operations, improving efficiency, and driving profitability. By integrating various business functions into a centralized system, ERP software provides real-time visibility, enhanced collaboration, and optimized decision-making.

One of the key advantages of ERP software is its ability to streamline the production process. By providing a comprehensive view of inventory, orders, and production schedules, ERP software enables manufacturers to optimize resource allocation, reduce lead times, and improve overall efficiency.

Additionally, ERP software automates many repetitive tasks, such as order processing, inventory management, and production scheduling, freeing up employees to focus on more value-added activities.

Cost Savings and Increased Profitability

ERP software implementation can lead to significant cost savings for assemble-to-order manufacturers. By optimizing inventory levels, reducing waste, and improving production efficiency, ERP software helps manufacturers reduce their operating expenses. Additionally, ERP software can improve revenue generation by enabling manufacturers to respond more quickly to customer demands and offer customized products and services.

Enhanced Customer Satisfaction and Improved Order Fulfillment

ERP software plays a crucial role in enhancing customer satisfaction and improving order fulfillment capabilities. By providing real-time visibility into order status, inventory availability, and production schedules, ERP software enables manufacturers to communicate accurate delivery dates to customers and respond promptly to changes in demand.

Additionally, ERP software facilitates seamless collaboration between sales, production, and logistics teams, ensuring that orders are fulfilled accurately and on time.

Key Features of ERP Software for Assemble-to-Order Manufacturing

ERP software for assemble-to-order manufacturing provides a comprehensive suite of features that support the unique requirements of this production environment. These features enable manufacturers to efficiently plan, schedule, and manage production, inventory, orders, and customer relationships.

Production Planning and Scheduling

ERP software for assemble-to-order manufacturing includes robust production planning and scheduling capabilities that help manufacturers optimize production processes. These features enable manufacturers to:

- Create and manage production plans and schedules based on customer orders and demand forecasts.

- Assign resources, including materials, labor, and equipment, to production orders.

- Track production progress in real-time and make adjustments as needed.

- Identify and resolve production bottlenecks and inefficiencies.

Inventory Management, ERP software for assemble-to-order manufacturing

Inventory management is critical for assemble-to-order manufacturers, as they need to ensure they have the right materials and components on hand to fulfill customer orders. ERP software for assemble-to-order manufacturing provides comprehensive inventory management capabilities that help manufacturers:

- Track inventory levels in real-time.

- Manage inventory replenishment and avoid stockouts.

- Optimize inventory levels to reduce carrying costs.

- Identify and manage obsolete or slow-moving inventory.

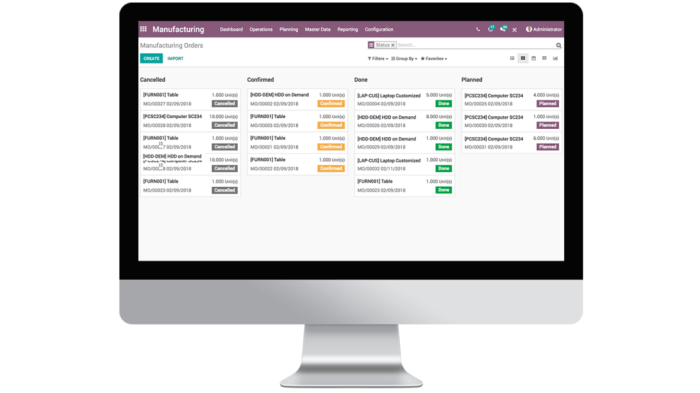

Order Management

ERP software for assemble-to-order manufacturing provides robust order management capabilities that help manufacturers efficiently process and fulfill customer orders. These features enable manufacturers to:

- Receive and manage customer orders.

- Create and track production orders based on customer orders.

- Track order progress and communicate with customers about order status.

- Process and track shipments and invoices.

Customer Relationship Management (CRM)

CRM is an essential component of ERP software for assemble-to-order manufacturing, as it enables manufacturers to build and maintain strong relationships with their customers. CRM features in ERP software help manufacturers:

- Manage customer contact information.

- Track customer interactions and preferences.

- Provide personalized customer service.

- Identify and target potential customers.

Challenges of Implementing ERP Software for Assemble-to-Order Manufacturing

Implementing ERP software in assemble-to-order manufacturing environments presents unique challenges that must be carefully considered to ensure a successful implementation. These challenges stem from the complexities of managing a high volume of orders with varying specifications, the need for real-time visibility into inventory and production, and the coordination of multiple departments involved in the manufacturing process.

Data Migration

One of the biggest challenges in implementing ERP software for assemble-to-order manufacturing is the migration of data from legacy systems. This data includes product information, customer orders, inventory levels, and production schedules. The accuracy and completeness of this data are crucial for the successful implementation of the ERP system.

Strategies for overcoming this challenge include:

- Conducting a thorough data audit to identify and correct any errors or inconsistencies in the legacy data.

- Developing a comprehensive data migration plan that Artikels the steps involved in migrating the data to the new ERP system.

- Testing the migrated data thoroughly to ensure its accuracy and completeness.

Best Practices for Selecting ERP Software for Assemble-to-Order Manufacturing

Selecting the right ERP software for assemble-to-order manufacturers is crucial for optimizing operations and achieving business success. Here are some best practices to guide you through the evaluation and selection process:

Assess Your Business Needs:Determine your specific requirements based on your manufacturing processes, product complexity, order fulfillment cycle time, and integration needs with other systems.

Evaluate Software Vendors

- Industry Expertise:Choose vendors with a proven track record in assemble-to-order manufacturing and a deep understanding of the industry’s challenges.

- Scalability:Ensure the software can accommodate your current and future growth plans, including the ability to handle increased order volume and product variations.

- Functionality:Verify that the software includes essential modules for assemble-to-order manufacturing, such as order management, inventory control, production planning, and quality management.

Conduct Software Demos

- Real-Time Simulations:Request demos that simulate your actual manufacturing processes to assess the software’s functionality and user-friendliness.

- Customization Options:Explore the software’s ability to be customized to meet your specific business requirements and integrate with your existing systems.

- Training and Support:Evaluate the vendor’s training and support offerings to ensure you have the necessary resources for a successful implementation and ongoing use.

Ensure Successful Implementation

- Project Planning:Develop a comprehensive implementation plan that includes timelines, resources, and communication channels.

- Data Migration:Plan for the seamless migration of data from your existing systems to the new ERP software.

- User Training:Provide thorough training to all users to ensure they understand the software’s functionality and can utilize it effectively.

Case Studies of Successful ERP Implementations in Assemble-to-Order Manufacturing

ERP systems have revolutionized assemble-to-order manufacturing, enabling companies to streamline operations, improve efficiency, and enhance customer satisfaction. Here are some notable case studies of successful ERP implementations in this industry:

Case Study 1: XYZ Manufacturing

- XYZ Manufacturing, a leading provider of custom-engineered machinery, implemented an ERP system to manage its complex manufacturing processes.

- The system integrated order management, inventory control, production scheduling, and quality control, providing real-time visibility into the entire manufacturing process.

- As a result, XYZ Manufacturing experienced a 20% reduction in lead times, a 15% increase in production capacity, and improved customer satisfaction.

Case Study 2: ABC Electronics

- ABC Electronics, a manufacturer of electronic components, implemented an ERP system to streamline its supply chain and improve inventory management.

- The system provided real-time visibility into inventory levels, enabling ABC Electronics to optimize production schedules and reduce inventory costs.

- The implementation resulted in a 10% reduction in inventory carrying costs, a 15% increase in inventory turnover, and improved customer service.

Lessons Learned from Successful ERP Implementations

- Thorough Planning:Successful ERP implementations require thorough planning, including a clear understanding of business requirements and a well-defined implementation plan.

- User Adoption:Ensuring user adoption is crucial. Training and support should be provided to help users understand and utilize the system effectively.

- Data Integrity:Maintaining data integrity is essential. Data should be accurate, complete, and consistent to ensure the system provides reliable information.

- Continuous Improvement:ERP systems should be continuously reviewed and updated to align with changing business needs and technological advancements.

Emerging Trends in ERP Software for Assemble-to-Order Manufacturing

The landscape of ERP software for assemble-to-order manufacturing is constantly evolving, driven by advancements in technology and the changing needs of businesses. Here are some of the latest trends and advancements shaping the future of the industry:

Cloud-based ERP Systems

Cloud-based ERP systems have gained immense popularity in recent years, offering numerous benefits such as reduced infrastructure costs, increased flexibility, and enhanced scalability. Assemble-to-order manufacturers can leverage cloud-based ERP systems to streamline their operations, improve collaboration, and gain real-time insights into their business performance.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are transforming ERP systems, enabling them to automate complex tasks, improve decision-making, and optimize processes. Assemble-to-order manufacturers can utilize AI and ML capabilities to enhance demand forecasting, optimize inventory management, and improve production planning.

IoT Integration

The Internet of Things (IoT) is connecting devices and machines across the manufacturing floor, generating vast amounts of data. ERP systems are integrating with IoT devices to capture and analyze this data, providing manufacturers with real-time visibility into their operations.

This enables them to identify inefficiencies, optimize production processes, and improve product quality.

Customization and Flexibility

ERP systems are becoming increasingly customizable and flexible, allowing manufacturers to tailor them to their specific business needs. This flexibility enables assemble-to-order manufacturers to adapt their ERP systems as their business evolves and new requirements arise.

Sustainability and Compliance

Sustainability and compliance are becoming increasingly important for assemble-to-order manufacturers. ERP systems are incorporating features that help manufacturers track and manage their environmental impact and ensure compliance with industry regulations.

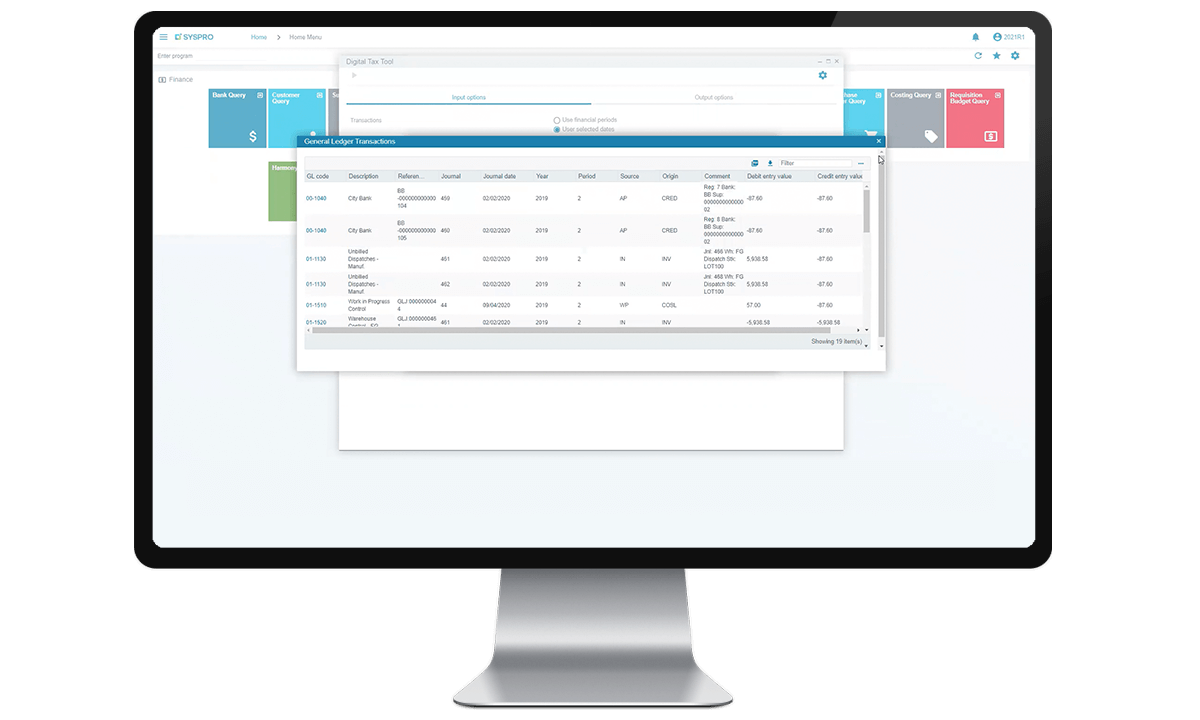

Integration of ERP Software with Other Systems: ERP Software For Assemble-to-order Manufacturing

Integrating ERP software with other systems is crucial for optimizing data sharing and streamlining processes within assemble-to-order manufacturing. This integration enables the seamless exchange of information between various systems, reducing the risk of data inconsistencies and errors.

CRM Integration

CRM (Customer Relationship Management) integration allows ERP software to access customer data, such as order history, preferences, and communication records. This integration improves customer service by providing a comprehensive view of customer interactions and enabling personalized marketing campaigns.

PLM Integration

PLM (Product Lifecycle Management) integration connects ERP software with the product development process. This integration facilitates the sharing of product specifications, design changes, and engineering data between ERP and PLM systems. It enhances collaboration between engineering and manufacturing teams, ensuring that products meet customer requirements and are manufactured efficiently.

MES Integration

MES (Manufacturing Execution System) integration provides real-time data on production processes to ERP software. This integration enables the monitoring of production schedules, equipment performance, and quality control. By providing real-time insights, MES integration helps identify and resolve production issues promptly, optimizing production efficiency and reducing downtime.

Future of ERP Software for Assemble-to-Order Manufacturing

ERP software is poised to play an increasingly important role in assemble-to-order manufacturing. As manufacturers strive to become more efficient and responsive to customer demand, they will need to adopt ERP systems that can provide them with the real-time data and insights they need to make informed decisions.

One of the most significant trends in the future of ERP software for assemble-to-order manufacturing is the increasing use of artificial intelligence (AI) and machine learning (ML). AI and ML can be used to automate many of the tasks that are currently performed manually, such as demand forecasting, inventory management, and scheduling.

This can free up manufacturers to focus on more strategic initiatives, such as product development and customer service.

Another trend that is likely to shape the future of ERP software for assemble-to-order manufacturing is the increasing adoption of cloud-based systems. Cloud-based ERP systems offer a number of advantages over on-premises systems, such as lower costs, greater flexibility, and easier access to data.

Potential Impact of Emerging Technologies

The future of ERP software for assemble-to-order manufacturing is bright. As manufacturers adopt new technologies such as AI, ML, and cloud computing, they will be able to improve their efficiency, responsiveness, and profitability.

Final Conclusion

ERP software has emerged as a cornerstone of modern assemble-to-order manufacturing, driving operational excellence and customer satisfaction. Its ability to streamline processes, reduce costs, and enhance agility has made it an indispensable tool for businesses seeking to thrive in today’s competitive landscape.

As technology continues to evolve, ERP software will undoubtedly play an even more pivotal role in the future of assemble-to-order manufacturing. With the integration of emerging technologies such as artificial intelligence and machine learning, ERP systems will become even more intelligent and responsive, enabling manufacturers to achieve unprecedented levels of efficiency and profitability.

Frequently Asked Questions

What are the key benefits of ERP software for assemble-to-order manufacturing?

ERP software streamlines operations, improves efficiency, reduces costs, enhances customer satisfaction, and provides a competitive advantage.

What are the essential features of ERP software for assemble-to-order manufacturing?

Essential features include production planning and scheduling, inventory management, order management, and customer relationship management (CRM).

What are the challenges of implementing ERP software for assemble-to-order manufacturing?

Challenges include data migration, user training, and ensuring a smooth integration with existing systems.