ERP software for configure-to-order manufacturing is a powerful tool that can help businesses streamline their operations, reduce lead times, and improve production efficiency. This guide will provide an overview of the benefits, key features, challenges, and best practices of ERP software for configure-to-order manufacturing.

ERP systems are designed to integrate with other software, such as CAD/CAM and PLM, to provide a comprehensive view of the manufacturing process. This integration can help to eliminate data silos and improve communication between different departments.

Benefits of ERP Software for Configure-to-Order Manufacturing

ERP software offers numerous benefits for configure-to-order manufacturing, streamlining order processing, reducing lead times, and improving production efficiency. It integrates with other software, such as CAD/CAM and PLM, providing a comprehensive solution for managing the entire manufacturing process.

Streamlined Order Processing

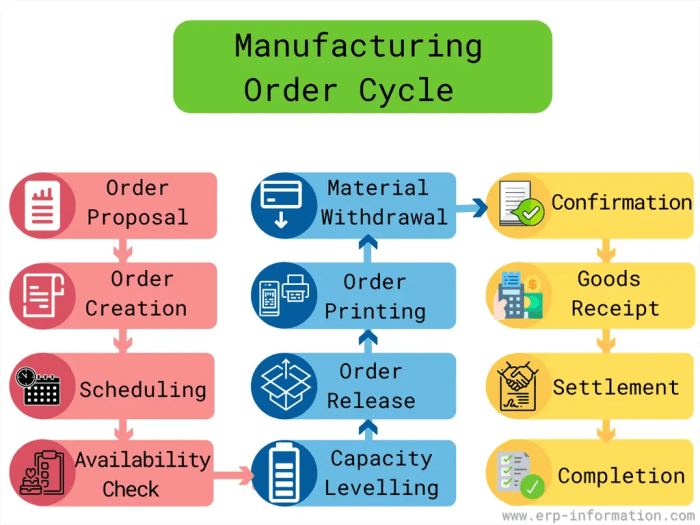

ERP systems automate the order processing workflow, reducing manual tasks and errors. They provide a centralized platform for capturing customer orders, configuring products based on specifications, and generating production orders. This streamlines the process, reduces order cycle times, and improves customer satisfaction.

Reduced Lead Times, ERP software for configure-to-order manufacturing

ERP software helps manufacturers reduce lead times by optimizing production planning and scheduling. It provides real-time visibility into inventory levels, material availability, and production capacity. This enables manufacturers to allocate resources effectively, identify bottlenecks, and adjust schedules accordingly, resulting in shorter lead times and improved on-time delivery performance.

Improved Production Efficiency

ERP systems enhance production efficiency by providing integrated tools for production planning, scheduling, and monitoring. They optimize production processes, reduce waste, and improve overall equipment effectiveness. By automating repetitive tasks, such as material requisition and work order creation, ERP software frees up manufacturing personnel to focus on value-added activities, leading to increased productivity.

Key Features of ERP Software for Configure-to-Order Manufacturing

ERP software for configure-to-order (CTO) manufacturing is designed to support the unique requirements of businesses that produce customized products based on customer specifications. Key features of such ERP software include:

Product Configurator

Product configurators allow customers to specify the exact features and options they want in their products. This ensures that each product is tailored to the customer’s specific needs and reduces the risk of errors in order fulfillment.

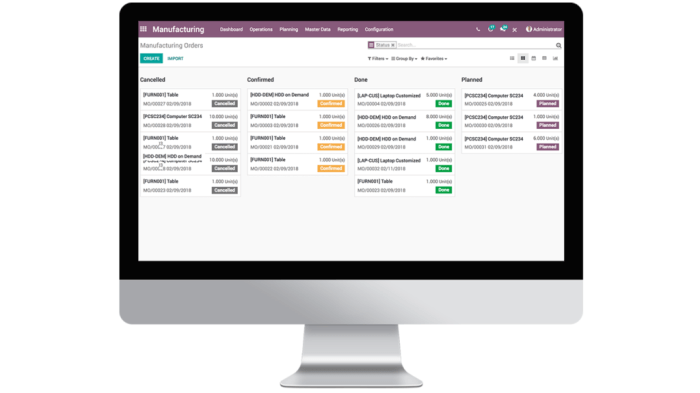

Order Management

Order management modules track the progress of customer orders from initial quote to final delivery. This provides real-time visibility into the status of each order, enabling manufacturers to proactively address any issues and ensure timely delivery.

Inventory Management

Inventory management modules ensure that manufacturers have the necessary components and materials on hand to fulfill customer orders. This reduces the risk of stockouts and delays, improving customer satisfaction and profitability.

Challenges of Implementing ERP Software for Configure-to-Order Manufacturing

Implementing ERP software in configure-to-order manufacturing environments presents unique challenges that require careful consideration and planning. Overcoming these hurdles is essential for ensuring a successful implementation and realizing the full benefits of the software.

Data Integration

One of the primary challenges lies in integrating data from multiple sources, including product specifications, customer orders, and manufacturing processes. This data integration ensures a seamless flow of information throughout the manufacturing process.

- Establish clear data standards and protocols to ensure data consistency and accuracy.

- Utilize data integration tools to automate the process of transferring data between different systems.

- Implement data validation procedures to identify and correct errors in the integrated data.

Process Standardization

Configure-to-order manufacturing often involves complex and varied processes, making it challenging to standardize them. However, standardization is crucial for efficient and effective ERP implementation.

- Develop clear and well-defined process documentation to guide users.

- Establish a central repository for process documentation to ensure accessibility and consistency.

- Train users on standardized processes and provide ongoing support to ensure adherence.

Best Practices for Implementing ERP Software for Configure-to-Order Manufacturing

ERP software implementation in configure-to-order manufacturing requires a structured approach to ensure seamless integration and optimal performance. Best practices include thorough project planning, meticulous data migration, and comprehensive user training.

Project Planning

Effective project planning lays the foundation for a successful ERP implementation. It involves defining clear project goals, establishing a timeline, allocating resources, and identifying potential risks. The project plan should Artikel the scope of the implementation, including the modules to be implemented, the data to be migrated, and the user training requirements.

Data Migration

Data migration is a critical aspect of ERP implementation. It involves transferring data from existing systems to the new ERP system. The data should be cleansed and validated to ensure accuracy and consistency. Proper data mapping and conversion techniques are essential to preserve data integrity and avoid errors.

User Training

User training is paramount for successful ERP implementation. It empowers users with the knowledge and skills to effectively utilize the system. Training should cover all aspects of the ERP system, including order entry, product configuration, inventory management, and reporting. Hands-on training and real-world simulations are highly effective in ensuring user proficiency.

Case Studies of Successful ERP Implementations for Configure-to-Order Manufacturing

ERP software has helped numerous configure-to-order manufacturers streamline their operations and improve efficiency. Here are a few case studies of successful ERP implementations:

Company A, a leading manufacturer of industrial machinery, implemented an ERP system to manage its complex configure-to-order processes. The system enabled the company to automate order processing, reduce lead times, and improve customer satisfaction. The company also reported a significant increase in sales and profitability after implementing the ERP system.

Company B, a manufacturer of medical devices, implemented an ERP system to improve its supply chain management and inventory control. The system helped the company reduce inventory costs, improve delivery times, and increase customer satisfaction. The company also reported a significant increase in sales and profitability after implementing the ERP system.

Lessons Learned from Successful ERP Implementations

Companies that have successfully implemented ERP software for configure-to-order manufacturing have shared some common lessons learned:

- Get buy-in from all stakeholders.It is important to get buy-in from all stakeholders, including employees, customers, and suppliers, before implementing an ERP system. This will help ensure that the system is implemented successfully and meets the needs of all stakeholders.

- Choose the right ERP software.There are many different ERP software solutions available, so it is important to choose the one that is right for your business. Consider your specific needs and requirements when choosing an ERP system.

- Implement the ERP system carefully.ERP system implementations can be complex, so it is important to implement the system carefully and according to best practices. This will help ensure that the system is implemented successfully and meets your business needs.

- Train your employees on the ERP system.It is important to train your employees on the ERP system so that they can use it effectively. This will help ensure that the system is used to its full potential and meets your business needs.

- Monitor the ERP system and make adjustments as needed.Once the ERP system is implemented, it is important to monitor the system and make adjustments as needed. This will help ensure that the system continues to meet your business needs.

Trends in ERP Software for Configure-to-Order Manufacturing

The ERP software landscape for configure-to-order manufacturing is constantly evolving, driven by technological advancements and changing business needs. Key trends shaping the future of ERP systems in this industry include:

Cloud-based solutions

Cloud-based ERP solutions are becoming increasingly popular due to their scalability, flexibility, and cost-effectiveness. These solutions allow manufacturers to access their ERP systems from anywhere, on any device, without the need for on-premises infrastructure.

Artificial intelligence (AI)

AI is transforming ERP systems by automating tasks, improving decision-making, and providing real-time insights. AI-powered ERP systems can analyze vast amounts of data to identify trends, predict demand, and optimize production schedules.

Internet of Things (IoT)

IoT devices are connecting machines and sensors throughout the manufacturing process, providing real-time data on equipment performance, inventory levels, and product quality. ERP systems are integrating with IoT data to improve visibility, control, and efficiency.

Vendor Landscape for ERP Software for Configure-to-Order Manufacturing

The vendor landscape for ERP software for configure-to-order manufacturing is diverse, with a range of vendors offering solutions tailored to the specific needs of this industry.

Some of the key vendors in this space include SAP, Oracle, Infor, Microsoft Dynamics, and Epicor. These vendors offer a comprehensive suite of ERP modules that support all aspects of configure-to-order manufacturing, from product configuration and engineering to order fulfillment and customer service.

Strengths and Weaknesses of Different Vendors

- SAPoffers a comprehensive ERP suite with a strong focus on manufacturing. SAP’s ERP software is used by some of the world’s largest configure-to-order manufacturers, including Boeing and Airbus.

- Oracleoffers a cloud-based ERP suite that is well-suited for configure-to-order manufacturers. Oracle’s ERP software is used by a number of leading manufacturers, including Dell and HP.

- Inforoffers a range of ERP solutions that are specifically designed for configure-to-order manufacturers. Infor’s ERP software is used by a number of leading manufacturers, including Caterpillar and John Deere.

- Microsoft Dynamicsoffers a cloud-based ERP suite that is well-suited for small and mid-sized configure-to-order manufacturers. Microsoft Dynamics ERP software is used by a number of leading manufacturers, including Stryker and Stanley Black & Decker.

- Epicoroffers a range of ERP solutions that are specifically designed for configure-to-order manufacturers. Epicor’s ERP software is used by a number of leading manufacturers, including Emerson and ITT.

Return on Investment (ROI) of ERP Software for Configure-to-Order Manufacturing

Calculating the ROI of ERP software for configure-to-order (CTO) manufacturing involves assessing the financial benefits gained from implementing the system against the costs of acquisition and implementation. Key metrics used to measure ROI include increased sales, reduced costs, improved efficiency, and enhanced customer satisfaction.

Improved Profitability

- Increased sales:ERP systems provide real-time visibility into customer demand, enabling manufacturers to respond quickly to changing market trends and offer customized products that meet specific customer needs. This can lead to increased sales and market share.

- Reduced costs:ERP systems automate many manual processes, reducing labor costs and improving efficiency. They also provide better control over inventory and supply chain management, leading to reduced waste and lower procurement costs.

Reduced Costs

- Improved efficiency:ERP systems streamline production processes, reducing lead times and improving overall efficiency. This can lead to lower production costs and increased productivity.

- Enhanced customer satisfaction:ERP systems improve communication and collaboration between different departments, ensuring that customer orders are processed accurately and efficiently. This leads to improved customer satisfaction and increased repeat business.

ERP Software Selection Criteria for Configure-to-Order Manufacturing

Selecting the right ERP software for configure-to-order (CTO) manufacturing is crucial to optimize operations and gain a competitive advantage. Here are the key criteria to consider:

Functionality

- Product Configuration:Ensure the software supports complex product configurations with multiple options and constraints.

- Engineering Change Management:Choose software that allows for efficient management of engineering changes throughout the product lifecycle.

- Sales Order Management:Look for software that integrates with CRM systems and automates order entry and processing.

- Production Planning and Scheduling:Select software that provides advanced planning and scheduling capabilities to optimize production for CTO environments.

- Inventory Management:Choose software that supports multi-level BOMs and provides real-time inventory visibility.

Scalability

Consider the scalability of the software to meet future growth and expansion plans. The software should be able to handle increased order volumes, product complexity, and manufacturing capacity.

Cost

Evaluate the total cost of ownership, including software licensing, implementation, training, and ongoing maintenance. Consider the potential return on investment (ROI) and the long-term benefits of the software.

Other Factors

- Vendor Reputation:Research the reputation of the software vendor in the CTO manufacturing industry.

- Implementation Experience:Choose a vendor with experience in implementing ERP software for CTO manufacturers.

- Customer Support:Ensure the vendor provides comprehensive customer support and technical assistance.

- User Interface:Consider the user-friendliness and ease of use of the software for both technical and non-technical users.

Final Thoughts: ERP Software For Configure-to-order Manufacturing

ERP software can be a valuable investment for businesses that manufacture configure-to-order products. By implementing ERP software, businesses can improve their efficiency, reduce costs, and gain a competitive advantage.

Top FAQs

What are the benefits of ERP software for configure-to-order manufacturing?

ERP software can help businesses streamline their operations, reduce lead times, and improve production efficiency.

What are the key features of ERP software for configure-to-order manufacturing?

The key features of ERP software for configure-to-order manufacturing include product configurator, order management, and inventory management.

What are the challenges of implementing ERP software for configure-to-order manufacturing?

The challenges of implementing ERP software for configure-to-order manufacturing include data integration and process standardization.

What are the best practices for implementing ERP software for configure-to-order manufacturing?

The best practices for implementing ERP software for configure-to-order manufacturing include project planning, data migration, and user training.